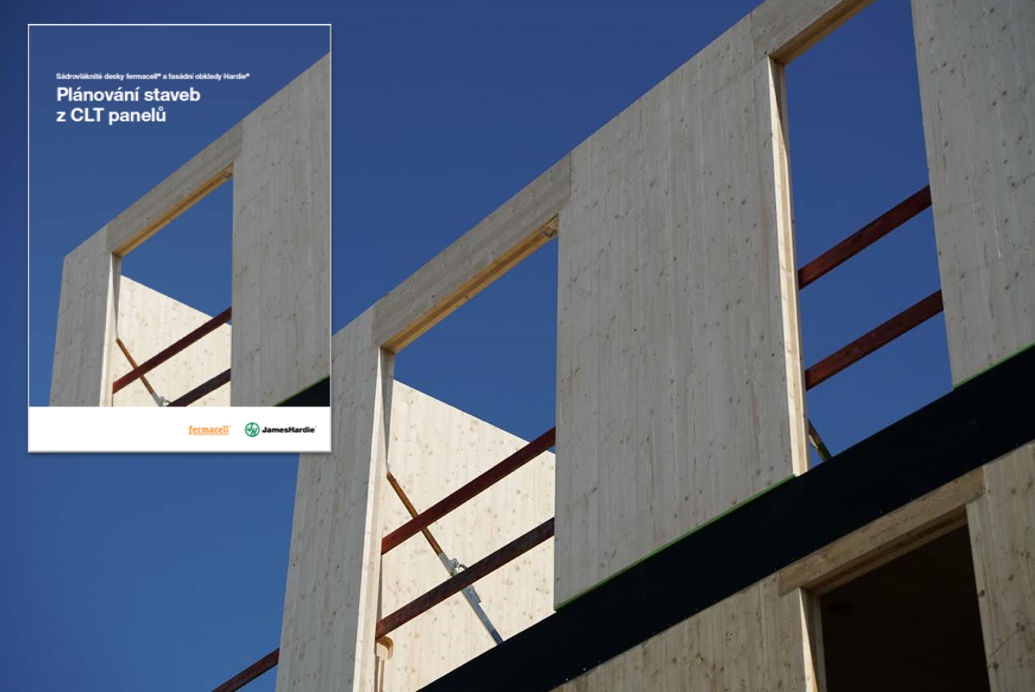

<div>Apartment buildings in Žďár nad Sázavou showcase the advantages of prefabricated structures made from CLT panels</div>

|

Project of apartment buildings in Žďár nad Sázavou was created according to the design of the studio Kuba & Pilař architects in collaboration with a private investor and local government, offering more than thirty available housing units for employees in key professions. It is a complex of two apartment buildings with a load-bearing structure made of CLT panels, complemented by an elevator shaft and a reinforced concrete staircase. Approximately 1,800 m² of fermacell® fiber cement boards are used in the wall structures of the two apartment buildings.

|

CLT panels have gained considerable attention from architects and builders in recent years due to their numerous advantages and potential for sustainable construction. In addition to being environmentally friendly and having construction properties (strength, stability, load-bearing capacity while being lightweight) or high construction efficiency, these panels offer an attractive surface finish and the ability to design modern and very pleasant spaces. The visible wood of the CLT panels can be exposed or concealed as needed, allowing architects to create visually appealing spaces that highlight the natural beauty of this material. The versatility of the design thus allows for various architectural styles and configurations to be realized in the interior. Along with suitable cladding, such as fermacell® fiber cement materials, the construction made of CLT panels also offers excellent fire-resistant properties.

|

Thanks to the use of modern prefabrication (up to 80%, which shortens construction time by half), Nema Dřevostavby quickly, affordably, and ecologically realizes both buildings

Construction from wood here demonstrates its main advantages – it is dry, clean, and up to twice as fast as brick. Moreover, it is sustainable, which is the focus of society today. Developers thus have the opportunity to see the key and undeniable advantages of timber constructions, and Nema, according to the words of CEO Tomáš Nemrava, expects Žďár nad Sázavou to become an inspiration for solving the housing shortage for other cities.

1,200 m³ of wood was used in the CLT panel apartment buildings

The load-bearing structure of the buildings consists of wooden wall and ceiling CLT panels. The exterior facade is designed in two combinations. The first is a contact thermal insulation system made of mineral wool, finished with a thin-layer creative plaster. The second is a ventilated wooden facade, whose visible part is made of larch battens on an aluminum grid. All structures are clad with fermacell® fiber cement boards. |

Composition of fermacell® constructions:

- peripheral panel (CLT) with fermacell® fiber cement boards

- peripheral panel (frame construction) with fermacell® fiber cement boards

- internal wall (frame construction) with fermacell® fiber cement boards

- internal wall (CLT) with fermacell® fiber cement boards

- inter-apartment walls (2×CLT) with fermacell® fiber cement boards

|

|

From detail to realization: fermacell® offers a systematic solution for CLT constructions

"The qualitative and time benefits of the CLT building method are clearly supported by our fermacell® fiber cement boards, which, with their technical and building-physical properties, are a suitable complement in this technology of construction. They score with quick and easy prefabrication in production. They are stable, highly load-bearing, and resistant to mechanical stress. They are equally suitable for wall, ceiling, and floor constructions, as well as for finishing attractive bathrooms," says Aleš Pechtor, regional manager – manager for industrial customers of James Hardie Europe, adding: "fermacell® also offers a range of proven fire protection solutions for constructions made of CLT panels. The designers at Nema were able to rely on the findings that our new publication 'Planning Buildings from CLT Panels' summarizes in a comprehensive form."Example of cladding solutions for CLT panels with fermacell® fiber cement board

|

Wood has proven itself as a building material for centuries

However, with the industrial revolution in the 19th century and the need to build a large number of houses quickly for people moving to cities for work, wood was replaced by new building materials that could be produced in large quantities. Wooden constructions were for a long time just fillers for voids. However, with growing ecological awareness, wood is being rediscovered as a valuable and sustainable building material that conserves resources.Cross-laminated timber or CLT is a large-area solid wood panel made up of at least three layers glued at right angles to each other

Solid panels are durable, have high dimensional stability, and due to their technical and building-physical properties, they represent a serious competition to concrete and steel. Unlike other construction methods, however, the production of cross-laminated timber requires very little energy. Like all wooden building materials, CLT stores CO2, thereby permanently contributing to climate protection. Due to the high degree of prefabrication, where elements are manufactured in factories under ideal conditions regardless of the weather, the construction time is short. Openings for windows and doors are easily cut out. Good diffusion properties create a pleasant indoor climate.With the development of multi-story wooden constructions, cross-laminated timber (CLT) structures are gaining importance

In 2022 alone, the production of CLT panels in the DACH region (including Italy and the Czech Republic) amounted to 1.22 million m³. A rise to 1.27 million m³ was expected in 2023. The global market for CLT panels is anticipated to grow from approximately $1.4 billion in 2023 to around $3.8 billion by 2030, with a year-on-year growth rate of nearly 15%. This trend is particularly reflected in the DACH region, where sustainability and ecological aspects are leading to the adoption of CLT as the preferred building material. This is not surprising: CLT panels meet all requirements for statics and stability, fire protection, and building physics. Production independent of weather conditions in the plant and a high degree of prefabrication ensure quick and technically flawless realization.The share of wooden constructions and hybrid wooden building systems in total construction volume has been steadily increasing for several years

This is also due to the fact that intensive and practice-oriented research has clarified many open questions regarding building constructions, statics, and building physics. In particular, the development of glued laminated timber (CLT), which has been on the market for just over 10 years, brings wooden constructions into buildings that could previously only be realized in concrete or steel. In addition to the construction of individual family and prefabricated homes as well as individual multi-story residential buildings, it is now also possible to realize large and high residential and office buildings in urban areas, commercial buildings, production halls, and even bridges without difficulties. Architects and designers thus have at their disposal a solid, rigid, and stable product that significantly facilitates the planning and realization of large timber construction projects due to its defined building-physical properties.Advantages of fermacell® systems in apartment buildings in Žďár nad Sázavou and other constructions made of CLT panels:

- 50 years of experience in timber constructions

- tested and certified system according to EN (ETA)

- fire safety

- acoustics

- mechanical resistance and stability

- 100% finely tuned system for prefabrication

- details and solutions

- cuttings tailored to the object

- waste optimization

- quick and efficient processing (e.g., glued joint)

- certified solutions for seals and penetrations

- wide range of surfaces and subsequent renovation

- load capacity up to 50 kg/m²

- surface finishing in the form of coatings, plasters, wallpapers, and fillers

- surfaces can be easily renovated without damaging the board

- CO2 neutral material

- varied facade systems (ETICS, plaster systems, ventilated facades)

Structures with CLT panels in the light of innovations and sustainability requirements

"In addition to certified and verified solutions backed by dozens of tests, James Hardie Europe offers investors, architects, designers, and contracting companies a range of innovative products. One of these is the special flooring elements for the fermacell® Therm25 underfloor heating system with low installation height and quick and easy installation. Naturally, there are also Environmental Product Declarations (EPD) and a well-thought-out waste management system with fermacell® materials," concludes Dipl.Ing. (FH) Jaroslav Benák, head of the technical department at James Hardie Europe. |

In the new publication "Fiber Cement Boards fermacell® and Hardie® Facades – Planning Buildings from CLT Panels" company James Hardie Europe takes into account the growing importance of cross-laminated timber constructions

The document is a summary of extensive system solutions that the manufacturer of fiber-cement Hardie® cladding and fermacell® fiber cement boards has developed for multi-story constructions with CLT panel structures. The publication also includes European solutions and shows examples of projects from Europe. Interested parties can download it free of charge in PDF format at www.fermacell.cz or www.jameshardie.cz in the Downloads section.

Basic information about the apartment buildings in Žďár nad Sázavou

Author: Kuba & Pilař architects, s. r. o.Investor: Affordable Housing of Česká spořitelna, a. s.

Location: Žďár nad Sázavou, Sázavská Street

Statics: Taros Nova, a. s.

Year of the project: 2023

Year of realization: 2024

Suppliers: Nema Dřevostavby, s. r. o., AUBÖCK s. r. o.

Height: 13 m

Amount of wood used: 1,200 m³

Amount of fermacell® boards used: 1,800 m²

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment