The new 5-ray administrative building of the energy company Statoil ASA is located on the premises of the former airport

In just 20 months, an architectural landmark was built in the city of Fornebu, near Oslo, on the grounds of the former airport. The new administrative building of the Norwegian energy company Statoil ASA gained admiration even during the development phase. The foundation of the building consists of a steel and concrete structure with a high degree of prefabrication and a painted sandwich façade made of aluminum elements from Schüco.

The relatively recently completed office building of Statoil ASA stands out with its timeless design, flexible structure, and environmentally friendly concept. It is located in the area of a former multi-storey car park in the Fornebu airport park, which closed in 1998. Since then, the spaces have gradually been transformed from airport to administrative use through the real estate agency IT Fornebu Properties AS.

Architectural Design

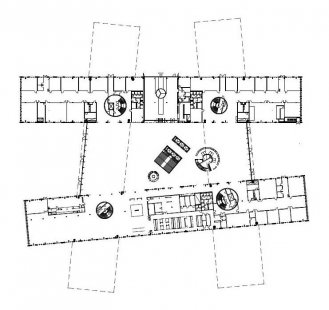

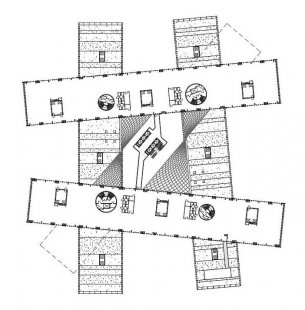

The design by the architectural office Arkitekturlaboratoriet AS (a-lab AS) won over competing proposals. The project, inspired by the globally renowned game Mikado, meets the requirement for the smallest possible footprint set in the grassy land of the former airport. It creates a flexible work environment with views of the surrounding fjords and aligns with the investor's corporate values. The open and outward-oriented architecture provides a working environment for 2,300 employees.

Structural Solution

The building consists of five rays, individually oriented and arranged across three levels. The individual arms touch at only four points. These overlapping spaces were utilized for placing central elevators and staircases. The defined center of the building features a 6-storey air-conditioned atrium with common areas. Each ray is 12.5 m high (three storeys), approximately 140 m long, and 23 m wide. The robust and stable steel structure allows for overhangs of up to 30 m.

High Degree of Prefabrication

The uniqueness of the project also lies in the extremely short construction time. The architectural office a-lab AS was informed in March 2009 about the task of designing a complex with an area of 65,500 m², including 52,400 m² of underground garages. At the beginning of 2010, right after the original garages were demolished, work began on the basement. During this time, intensive adjustments to the design concept of the building were still underway. Due to the tight construction schedule, the largest construction parts of the building, including steel and concrete structures and façade elements, were prefabricated and subsequently assembled on-site. The use of prefabricated structures ensured higher precision and accelerated processes. The 140-meter-long steel structures, manufactured in Finland, were transported by trucks in the form of 100-ton sections and then welded together. The largest mobile crane in Europe facilitated the handling and positioning of individual elements.

Cladding of the Building

While the steel structures of the upper rays were still being installed, Flex Fasader AB was already working on the cladding at the lower part. 80 mm wide façade profiles from Schüco International KG were used. They are highly stable and allow for the creation of façade elements measuring 3 x 4.7 m (width x height). On the long sides of the rays, the façade, composed of painted sandwich panels made of aluminum, creates interesting patterns that, from a distance, resemble a group of pixels. It was important for the architects that the cladding of the building appeared uniform, without any interruptions, even due to technical equipment. Therefore, a special façade cassette with a depth of 250 mm was created, where all technical components, including blinds, are hidden. This resulted in deeper façade elements that give the building a relief character while also serving as additional natural shading. The closed façade sections achieve a U-value of 0.18 W/m²K, while the glazed parts achieve U = 0.6 W/m²K. According to the architect, the ratio of 65% glazed and 35% solid parts provides an ideal balance between the admission of daylight and heat from solar radiation. A prototype of the façade was tested in advance at the Schüco Technology Center for resistance to water and wind.

Automated Shading

The dark shields of the rays, resembling a display or showcase, cannot go unnoticed. The black glass on this side of the façade, developed in collaboration between Flex Fasader AB and Schüco International KG, contrasts perfectly with the predominant white elements of the building. Each shield consists of 180 glass slats. They are secured at the top and bottom using special attachments derived from the standard Schüco ALB system for blinds. The glass slats were designed to slightly overlap while maintaining a uniform structure. They consist of black-tinted double glazing with a dark core, creating a deeply dark impression when viewed from the outside. Thanks to this solution, no further shading techniques are needed. The 4.2 m high slats are connected by a guide bar and, depending on the direction of sunlight, automatically shift to different positions in a linear manner according to a pre-set ideal model. When viewed from the inside, this unique shading is essentially invisible. Depending on the shading position, the G value of all movable glass elements ranges from 0.24 to 0.36 W/m²K.

The overall energy consumption of the building is calculated at 103 kWh/m². The energy efficiency of the building is supported by a number of factors, in addition to the highly thermally insulated façade elements and the aforementioned shading techniques, utilizing district heating and up to 85% energy recycling.

The building is a bold example of the creative use of prefabricated components and individualized standard elements, contributing to the expressive architecture of the future, which is anything but standard.

Location: Norway, Oslo / Fornebu

Investor/Client: IT Fornebu Properties ASA

Architect: Arkitekturlaboratoriet AS (a-lab AS)

Project Leader: Charlie Mardsen

User: Statoil ASA, Fornebu/NOR

Structural Engineer: Norconsult AS, Sandvika/NOR; RUUKKI steel, Helsinki/FIN

Technical Supervision: Hjellnes Consult AS, NOR/Oslo

Façade System: Flex Fasader AB, SWE; Schüco International KG, DE

Construction Period: 01/2010 - 09/2012

For more information about Schüco systems, visit www.schueco.cz

The relatively recently completed office building of Statoil ASA stands out with its timeless design, flexible structure, and environmentally friendly concept. It is located in the area of a former multi-storey car park in the Fornebu airport park, which closed in 1998. Since then, the spaces have gradually been transformed from airport to administrative use through the real estate agency IT Fornebu Properties AS.

Architectural Design

The design by the architectural office Arkitekturlaboratoriet AS (a-lab AS) won over competing proposals. The project, inspired by the globally renowned game Mikado, meets the requirement for the smallest possible footprint set in the grassy land of the former airport. It creates a flexible work environment with views of the surrounding fjords and aligns with the investor's corporate values. The open and outward-oriented architecture provides a working environment for 2,300 employees.

Structural Solution

The building consists of five rays, individually oriented and arranged across three levels. The individual arms touch at only four points. These overlapping spaces were utilized for placing central elevators and staircases. The defined center of the building features a 6-storey air-conditioned atrium with common areas. Each ray is 12.5 m high (three storeys), approximately 140 m long, and 23 m wide. The robust and stable steel structure allows for overhangs of up to 30 m.

High Degree of Prefabrication

The uniqueness of the project also lies in the extremely short construction time. The architectural office a-lab AS was informed in March 2009 about the task of designing a complex with an area of 65,500 m², including 52,400 m² of underground garages. At the beginning of 2010, right after the original garages were demolished, work began on the basement. During this time, intensive adjustments to the design concept of the building were still underway. Due to the tight construction schedule, the largest construction parts of the building, including steel and concrete structures and façade elements, were prefabricated and subsequently assembled on-site. The use of prefabricated structures ensured higher precision and accelerated processes. The 140-meter-long steel structures, manufactured in Finland, were transported by trucks in the form of 100-ton sections and then welded together. The largest mobile crane in Europe facilitated the handling and positioning of individual elements.

Cladding of the Building

While the steel structures of the upper rays were still being installed, Flex Fasader AB was already working on the cladding at the lower part. 80 mm wide façade profiles from Schüco International KG were used. They are highly stable and allow for the creation of façade elements measuring 3 x 4.7 m (width x height). On the long sides of the rays, the façade, composed of painted sandwich panels made of aluminum, creates interesting patterns that, from a distance, resemble a group of pixels. It was important for the architects that the cladding of the building appeared uniform, without any interruptions, even due to technical equipment. Therefore, a special façade cassette with a depth of 250 mm was created, where all technical components, including blinds, are hidden. This resulted in deeper façade elements that give the building a relief character while also serving as additional natural shading. The closed façade sections achieve a U-value of 0.18 W/m²K, while the glazed parts achieve U = 0.6 W/m²K. According to the architect, the ratio of 65% glazed and 35% solid parts provides an ideal balance between the admission of daylight and heat from solar radiation. A prototype of the façade was tested in advance at the Schüco Technology Center for resistance to water and wind.

Automated Shading

The dark shields of the rays, resembling a display or showcase, cannot go unnoticed. The black glass on this side of the façade, developed in collaboration between Flex Fasader AB and Schüco International KG, contrasts perfectly with the predominant white elements of the building. Each shield consists of 180 glass slats. They are secured at the top and bottom using special attachments derived from the standard Schüco ALB system for blinds. The glass slats were designed to slightly overlap while maintaining a uniform structure. They consist of black-tinted double glazing with a dark core, creating a deeply dark impression when viewed from the outside. Thanks to this solution, no further shading techniques are needed. The 4.2 m high slats are connected by a guide bar and, depending on the direction of sunlight, automatically shift to different positions in a linear manner according to a pre-set ideal model. When viewed from the inside, this unique shading is essentially invisible. Depending on the shading position, the G value of all movable glass elements ranges from 0.24 to 0.36 W/m²K.

The overall energy consumption of the building is calculated at 103 kWh/m². The energy efficiency of the building is supported by a number of factors, in addition to the highly thermally insulated façade elements and the aforementioned shading techniques, utilizing district heating and up to 85% energy recycling.

The building is a bold example of the creative use of prefabricated components and individualized standard elements, contributing to the expressive architecture of the future, which is anything but standard.

Basic Information About the Building

Building Name: New Regional Office of Statoil ASALocation: Norway, Oslo / Fornebu

Investor/Client: IT Fornebu Properties ASA

Architect: Arkitekturlaboratoriet AS (a-lab AS)

Project Leader: Charlie Mardsen

User: Statoil ASA, Fornebu/NOR

Structural Engineer: Norconsult AS, Sandvika/NOR; RUUKKI steel, Helsinki/FIN

Technical Supervision: Hjellnes Consult AS, NOR/Oslo

Façade System: Flex Fasader AB, SWE; Schüco International KG, DE

Construction Period: 01/2010 - 09/2012

For more information about Schüco systems, visit www.schueco.cz

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment

Related articles

0

10.01.2014 | Sample school facility for more than 3,000 children has risen in Luxembourg

2

08.07.2013 | Maintenance-free family house with clear specifications, smooth plaster finishes, and cedar and corten facades

0

18.03.2013 | Modern energy-efficient family house with a perfect view like from an observation tower