Composite materials for outdoor use

Composite materials with the international designation WPC - Wood Polymer Composites - have been on the market for about twenty years. Due to their durability and stability, they are ideal for outdoor use, most commonly for terrace surfaces and outdoor cladding of buildings, and in the future, they may completely replace wood as a construction material. These materials combine the advantages of wood and plastic, from which their mixture is made. At first glance, they are difficult to distinguish from wood, but they have much higher resistance to weather conditions and are practically maintenance-free (they just need to be occasionally rinsed with water).

Composites provide a neat, flat surface that feels like wood, but they don't splinter, slip, warp, or get infested by pests. Most importantly, they require no impregnation, coatings, or other maintenance, as they do not decompose. The warranty provided by most manufacturers is 25 years. Another advantage is the easy installation. Moreover, these materials are environmentally friendly, using wood waste (sawdust) or pine wood from sustainably managed forests, and no adhesives are added that could later release toxic formaldehyde into the air. They are 100% recyclable and represent an excellent alternative to hardwoods.

In our market of building materials, you will find WPC from several manufacturers. Their properties vary significantly depending on their composition, with the type of plastic used and the proportion of wood content being important. Materials containing PVC have better thermodynamic properties, are harder, more stable, and more resistant than those containing polyethylene and polypropylene. The proportion of the second component in the composite also plays a significant role. Besides wood, which is the best, sometimes cellulose pulp or rice husks are used in cheaper composites. According to past experiences, the ideal ratio is 50% PVC and 50% wood sawdust, which ensures sufficient strength of the material and a wood-like appearance. This combination can be found in the material Twinson, produced by Deceuninck.

O-Terrace+ is ideal for public spaces

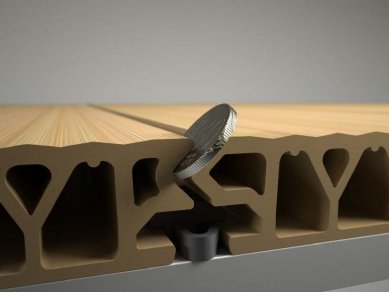

In June this year, Deceuninck launched a new system, Twinson O-Terrace+, representing a premium, very robust solution for outdoor terraces for commercial use. This system builds upon the previous Twinson O-Terrace, which has already proven fully suitable for terraces at family homes, pool surrounds, and other garden structures of smaller areas. The O-Terrace+ features a new wavy surface with an attractive look, and the semi-recessed groove between the boards adds style to the terrace area. Thanks to the tongue-and-groove system, no small items can fall through the gaps between the boards, yet there remains sufficient space for water drainage and ventilation. The Twinson O-Terrace+ has a higher load capacity and impact resistance. With the new "snap-in" clip & slide system that minimizes the use of screws, installation is simpler, and individual boards can be easily and quickly replaced. The wooden or aluminum substructure allows for increased strength, enabling the distance between support beams to be increased from the standard 50 cm to 60 cm. Installation is therefore faster, which is advantageous for large commercial areas. Additionally, the risk of deformation is eliminated thanks to the integrated clip between the boards that absorbs any potential expansion.

Both Twinson O-Terrace and Twinson O-Terrace+ offer eight pleasant color variants, which can be easily matched with the surrounding décor. More information about the new material can be found at www.deceuninck.cz.

Composites provide a neat, flat surface that feels like wood, but they don't splinter, slip, warp, or get infested by pests. Most importantly, they require no impregnation, coatings, or other maintenance, as they do not decompose. The warranty provided by most manufacturers is 25 years. Another advantage is the easy installation. Moreover, these materials are environmentally friendly, using wood waste (sawdust) or pine wood from sustainably managed forests, and no adhesives are added that could later release toxic formaldehyde into the air. They are 100% recyclable and represent an excellent alternative to hardwoods.

In our market of building materials, you will find WPC from several manufacturers. Their properties vary significantly depending on their composition, with the type of plastic used and the proportion of wood content being important. Materials containing PVC have better thermodynamic properties, are harder, more stable, and more resistant than those containing polyethylene and polypropylene. The proportion of the second component in the composite also plays a significant role. Besides wood, which is the best, sometimes cellulose pulp or rice husks are used in cheaper composites. According to past experiences, the ideal ratio is 50% PVC and 50% wood sawdust, which ensures sufficient strength of the material and a wood-like appearance. This combination can be found in the material Twinson, produced by Deceuninck.

O-Terrace+ is ideal for public spaces

In June this year, Deceuninck launched a new system, Twinson O-Terrace+, representing a premium, very robust solution for outdoor terraces for commercial use. This system builds upon the previous Twinson O-Terrace, which has already proven fully suitable for terraces at family homes, pool surrounds, and other garden structures of smaller areas. The O-Terrace+ features a new wavy surface with an attractive look, and the semi-recessed groove between the boards adds style to the terrace area. Thanks to the tongue-and-groove system, no small items can fall through the gaps between the boards, yet there remains sufficient space for water drainage and ventilation. The Twinson O-Terrace+ has a higher load capacity and impact resistance. With the new "snap-in" clip & slide system that minimizes the use of screws, installation is simpler, and individual boards can be easily and quickly replaced. The wooden or aluminum substructure allows for increased strength, enabling the distance between support beams to be increased from the standard 50 cm to 60 cm. Installation is therefore faster, which is advantageous for large commercial areas. Additionally, the risk of deformation is eliminated thanks to the integrated clip between the boards that absorbs any potential expansion.

Both Twinson O-Terrace and Twinson O-Terrace+ offer eight pleasant color variants, which can be easily matched with the surrounding décor. More information about the new material can be found at www.deceuninck.cz.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment