Dekprofile for architect

The call of architects has always been a combination of practicality and originality. The most distinctive part of any architectural work is its façade, through which the building speaks to its surroundings and defines its entire character.

In modern architecture, ventilated façades (definition in the infobox) are highly popular, offering many functional and aesthetic advantages. In recent years, these façades have undergone a significant transformation. With a wide selection of colors, surface materials, and a variety of shapes of visible elements, countless possibilities for creating an original façade are available.

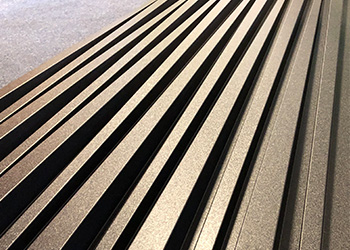

The company DEKMETAL is introducing a truly exceptional product that will provide relief to ventilated façades and impart the much-demanded originality in today's era. A ventilated façade doesn't have to be defined solely by a smooth panel; it can have its own shape, extending into space, and possess its own definition.

The new product line from Dekmetal is based on classic profiled sheets, utilizing all their advantages and innovating them into the modern architecture of the 21st century. DEKPROFILE FOR ARCHITECT from DEKMETAL offers architects the opportunity to create entirely unique curved profiles that will be distinctive for a specific building. The basic range of profiles is naturally available for personalization as well.

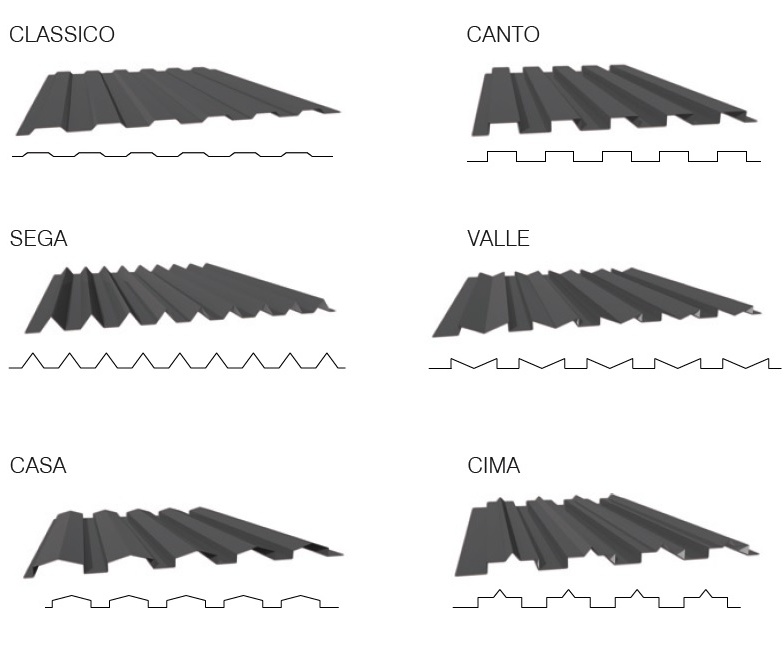

Dekprofile for architect offers 6 basic types of profiles with personalization options. It is very simple to adjust the size or length of folds, angles of folds, and lengths of straight transitions. This creates an entirely new profile precisely according to the investor's or architect's requirements. However, the options for modifications are even greater.

|

In modern architecture, ventilated façades (definition in the infobox) are highly popular, offering many functional and aesthetic advantages. In recent years, these façades have undergone a significant transformation. With a wide selection of colors, surface materials, and a variety of shapes of visible elements, countless possibilities for creating an original façade are available.

The company DEKMETAL is introducing a truly exceptional product that will provide relief to ventilated façades and impart the much-demanded originality in today's era. A ventilated façade doesn't have to be defined solely by a smooth panel; it can have its own shape, extending into space, and possess its own definition.

The new product line from Dekmetal is based on classic profiled sheets, utilizing all their advantages and innovating them into the modern architecture of the 21st century. DEKPROFILE FOR ARCHITECT from DEKMETAL offers architects the opportunity to create entirely unique curved profiles that will be distinctive for a specific building. The basic range of profiles is naturally available for personalization as well.

| A ventilated façade is characterized by a continuous vented gap that is created between the thermal insulation of the load-bearing structure and the visible elements. The airflow in the vented gap creates a chimney effect, which contributes to a better climate inside the building, significantly reduces the condensation of water vapor in the structure of the outer wall, and thus the potential risk of mold growth. Main advantages: Longer lifespan of the façade compared to contact insulation systems Maintenance-free system, option for local repairs Easy leveling of uneven substrate construction Healthier indoor climate in both winter and summer Better acoustic conditions in the interior The façade system is completely non-flammable The installation process is performed dry. No wet processes |

One profile, many possibilities

|

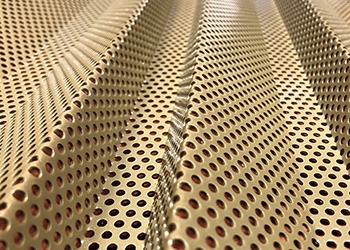

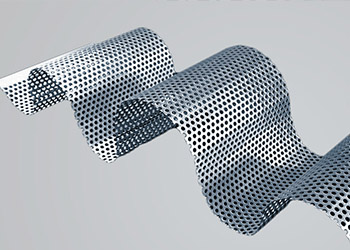

| 3D PROFILES | PERFORATION | BENT WAVES | |||

|

|

|

| Colors and materials The basic material consists of painted galvanized or aluminum sheets. Galvanized sheets S280-320GD ZM140 (alternatively Z275 or AZ150) are coated with a polyester (SP), PVDF, or polyurethane (PU) paint with a thickness of 25 - 60 microns (depending on the chosen type of surface treatment) in glossy, matte, and textured variants. Specific surface finishes and decors, such as wood or stone imitation, various degrees of copper patina, or TiZn, can also be supplied upon request. Additionally, metallic colors, crystallinely changing colors, or weather-resistant steel commonly known as Corten can be delivered. Production from non-ferrous sheets (TiZn, Cu) is also possible, supplied in natural, painted, or pre-weathered finishes. These treatments give the façade panels a very specific and unmistakable appearance. The basic color chart can be found here (https://dekmetal.cz/aktuality/vzornik) |

One profile, wide applications

Façades

Dekprofile for architect is intended for all types of buildings (administrative, civic, industrial, etc.). DEKMETAL profiles are part of the ventilated façade system of building cladding. Other components include a certified supporting framework, a complete system of flashing with roofing elements, and anchoring and fastening materials. Services are provided in the form of building measurement, preparation of complete technical documentation for the façade including tailored design details, and expert consulting throughout the project implementation. Training for implementing companies is also standard before and during construction.

Interiors, ceilings

Dekprofile for architect is an ideal choice for creating original interiors. Thanks to the possibility of creating custom designs and a wide range of materials, colors, and decors, they can be integrated into almost any space. DEKMETAL cladding elements can be used for partitions, dividing screens, counters, furniture parts, or ceilings.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment