Establishing family houses on thermal insulation fill made of Liapor (expanded clay)

|

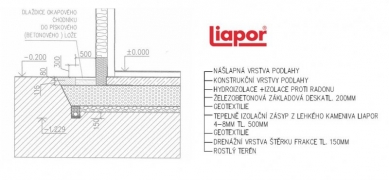

Foundations are among the most important parts of a building and are rightly subject to high demands. It pays off to critically select materials and carefully consider their properties when it comes to foundations. The choice of materials and technologies by designers and builders of family homes today should always aim towards those that help ensure the lowest possible energy demands during the use of the building. One such option is the innovative foundation of family homes on thermal insulating fill made from Liapor (expanded clay), which provides sufficient thermal insulating properties even for the construction of low-energy and passive family homes. Additionally, it has other advantages such as long lifespan, resistance, and health safety.

Basic Properties of Liapor Aggregate

Liapor is a lightweight ceramic aggregate (expanded clay), produced by firing and simultaneous expansion of natural granulated clays. This results in sintered ceramic grains with a uniformly porous internal structure, excelling primarily due to their physicochemical and mechanical properties. The properties of Liapor are the properties of a purely ceramic material, which makes Liapor ideal for a wide range of construction applications including the foundation of family homes.- Bulk Density: The porous structure of the grains gives Liapor a very low weight. For the purpose of building foundations, Liapor aggregate of fraction 4-8 mm is used with a bulk weight of 350 kg/m3.

- Thermal Conductivity: Due to its porous structure and ceramic nature, Liapor possesses excellent thermal insulating ability along with good accumulative properties - its thermal conductivity coefficient in the dry state is 0.0949 W/m.K.

- Compressive Strength: The grains of Liapor are nearly spherical, have a solid sintered surface and a uniformly porous core. This structure gives Liapor good strength even at very low weight. The strength of the grains further depends on the bulk density and the type of Liapor. Compressive strength is determined by pressing in a cylinder and ranges from 0.7 to 10 MPa.

- Durability: Liapor is also chemically stable. The grains resist acids and alkalis. In water, it is stable and neutral, does not dissolve, and does not release harmful leachates or gases.

- Fire Resistance: Liapor is created in fire and is fire resistant. It remains volume-stable up to a temperature of 1050 °C. As a material based on purely ceramic substance, Liapor is classified according to ČSN 73 0823 as a material with fire class A – non-flammable material.

- Frost Resistance: The porous, non-capillary structure of Liapor allows for the expansion of frozen water in the grains. Therefore, Liapor withstands repeated freezing and provides excellent frost resistance even for products in which it is used. The weight loss after 25 freeze cycles is up to 2%.

- Water Absorption: Liapor is not hygroscopic and does not absorb moisture from the air. Its natural equilibrium moisture is 0.2% by volume.

- Moisture: An undeniable advantage of Liapor is that it can be supplied in a perfectly dry state.

- Health Safety: Liapor consists of pure expanded natural clay, does not release any gaseous emissions or harmful leachates for humans.

Advantages of Foundation Using Liapor

- ideal homogeneous insulation layer without thermal bridges

- from a static point of view, layers can be placed from 0.5 to 1 m

- from a thermotechnical perspective, a layer of 0.5 m is sufficient

- additional floor insulation is not necessary, only in the case of heating systems (e.g., underfloor heating)

- the system of foundation on Liapor is suitable for the foundations of all types of buildings (prefabricated, monolithic, masonry)

|

Procedure for Foundation Using Liapor Aggregate

- Delivery of Liapor to the construction site is carried out by large-capacity dump trucks.

- The first layer of Liapor is laid on non-woven geotextile. The actual laying usually occurs manually, possibly with small conveyor machinery (depending on the size of the construction).

- Liapor is laid in 0.3 m layers up to the required thickness of the fill. Each layer is compacted with vibrating plates.

- The upper layer is covered with a thin cement slurry, creating a layer of porous concrete that is walkable. A foundation slab for a family house can be constructed on such prepared foundation joint.

Founding a house using Liapor can be realized by anyone who has experience with house foundations. The manufacturer of Liapor, Lias Vintířov, provides builders with free technical support and consultancy.

For more information, individual price offers, and orders, contact the sales and technical advisors at Lias Vintířov:

Lias Vintířov, lightweight building material k.s.,

A House in One Move

tel: +420 352 324 426

e-mail: info@djt.cz

web: www.dumjednimtahem.cz

The English translation is powered by AI tool. Switch to Czech to view the original text source.

1 comment

add comment

Subject

Author

Date

...

čičmák

02.04.13 10:14

show all comments