PREFALZ at a private observatory

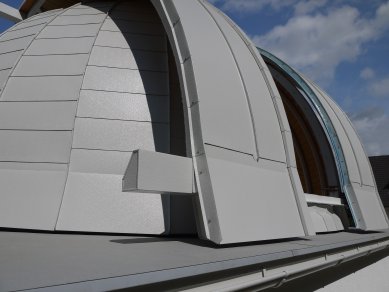

The private observatory is situated at an altitude of 350 m above sea level. The semi-spherical roof area with 24 corners and a height of 2.7 meters is 47.50 m2. The total coverage area, including the lower edge and both sides of the slit structure, reaches 58.5 m2. The roofing material used was lacquered aluminum seamed roofing Prefalz with a two-component lacquer PP 99 with a Stucco finish in white. The material consumption was significantly higher due to the method of covering the hemisphere with several hundred pieces, approximately 58% more than with standard installation. However, with a weight of the Prefalz sheet metal of about 2.2 kg/m2, the total weight of the roofing on the observatory still amounts to a "mere" 183.5 kg. The installation was carried out on a full substrate through hidden anchoring (stainless steel brackets in the standing seam). Roof accessories are made of the same material (trim, cladding, strips, gutters, window sills). The load capacity of the Prefalz covering reaches a maximum of 800 kg/m2.

The planetary observatory has a base of 6x6 m made of lost formwork. It is properly insulated and fitted with entrance doors and windows. Unconventionally, there are corner fireplace stoves and a smaller kitchen unit for preparing quick snacks. These ensure comfort in any season and independence from the surrounding environment.

The flat roof of the masonry square building – the base under the dome – consists of a slightly sloped chipboard layer with a 1.8 mm thick foil covering from the Norwegian Protan system. Under the dome, there is a 150 mm high circular collar, finished with cladding edges on the sides. Water drainage is ensured from three sides by aluminum undergutter gutters from PREFA in the color of the dome covering and two downspouts with a diameter of 80 mm. Window sills are custom-made from aluminum sheet Prefalz 0.7 mm thick (smooth white).

The dome of the observatory, built and supplied by Mr. Jiří Drbohlav Jr. from Rtyně in Podkrkonoší, is a hemisphere with a conical lower part – a skirt. The dome's structure rests on a load-bearing circular ring bent from steel I profiles with a total diameter of 5.4 meters. For its realization, it was necessary to manufacture a special bending machine worth several hundred thousand crowns. The circular ring, which serves as a rail for the movement of the dome, supports the roof structure of the observatory itself. It is also made of bent I profiles, interconnected with screws. The individual surfaces of the hemisphere converge at 24 "corners" and adhere to the collar of the load-bearing surrounding structure of the telescope’s observation slit. This is equipped with lateral slides with gates, which consist of two cylindrical surfaces, covering the slit with an overhang from the apex to the base of the dome. The entire roof structure is thoroughly measured and balanced to ensure its easy handling along the circular ring. Motorized control will be implemented in the future; however, the entire dome, weighing over 3 tons, can already be easily moved with just one hand!

On the metal structure, replacing the rafters, lies resonant timber, similar to that used for the production of musical instruments. Specifically, it consists of high-quality resonant battens made of spruce, which allow for a high degree of bending without losing the function and quality of the material. On the battens, a full planking (tongue-and-groove) 2.5 cm thick is laid transversely. This is followed by a protective waterproofing membrane and the grooved roofing material Prefalz. The final white shade was chosen considering both functionality and aesthetics. The rougher surface, known as stucco, ensures originality and reduced noise during rain.

The most optimal covering method chosen was simple horizontal seams on the flat area and double seaming at the corners. The cylindrical area of the retractable gates posed a challenge for the roofing. The zero and negative slope at the top of the gates was a critical point, and choosing a different covering method sparked debates about the final impression. Ultimately it was decided on continuous seams from top to bottom, requiring mechanical profiling and rolling into the desired radius of 2800 mm over a length of 5850 mm. The rolling took place directly on site. “We utilized the excellent service of PREFA Aluminiumprodukte. Thanks especially to Mr. Roman Vaňka for his willingness and dedication. We scheduled a date for May 15, 2014, and despite the very windy and uncertain weather that prevailed on that day, he arrived at the agreed hour with the RBM bending machine from Schlebach directly on site. On the "pampered" lawn of the investor's garden, we then "drew" the required arc with lime, and practically within 1 hour we had the roofing ready for installation. The final result is more than satisfactory,” specifies the roofer Jan Pavel.

The planetary observatory has a base of 6x6 m made of lost formwork. It is properly insulated and fitted with entrance doors and windows. Unconventionally, there are corner fireplace stoves and a smaller kitchen unit for preparing quick snacks. These ensure comfort in any season and independence from the surrounding environment.

The flat roof of the masonry square building – the base under the dome – consists of a slightly sloped chipboard layer with a 1.8 mm thick foil covering from the Norwegian Protan system. Under the dome, there is a 150 mm high circular collar, finished with cladding edges on the sides. Water drainage is ensured from three sides by aluminum undergutter gutters from PREFA in the color of the dome covering and two downspouts with a diameter of 80 mm. Window sills are custom-made from aluminum sheet Prefalz 0.7 mm thick (smooth white).

The dome of the observatory, built and supplied by Mr. Jiří Drbohlav Jr. from Rtyně in Podkrkonoší, is a hemisphere with a conical lower part – a skirt. The dome's structure rests on a load-bearing circular ring bent from steel I profiles with a total diameter of 5.4 meters. For its realization, it was necessary to manufacture a special bending machine worth several hundred thousand crowns. The circular ring, which serves as a rail for the movement of the dome, supports the roof structure of the observatory itself. It is also made of bent I profiles, interconnected with screws. The individual surfaces of the hemisphere converge at 24 "corners" and adhere to the collar of the load-bearing surrounding structure of the telescope’s observation slit. This is equipped with lateral slides with gates, which consist of two cylindrical surfaces, covering the slit with an overhang from the apex to the base of the dome. The entire roof structure is thoroughly measured and balanced to ensure its easy handling along the circular ring. Motorized control will be implemented in the future; however, the entire dome, weighing over 3 tons, can already be easily moved with just one hand!

On the metal structure, replacing the rafters, lies resonant timber, similar to that used for the production of musical instruments. Specifically, it consists of high-quality resonant battens made of spruce, which allow for a high degree of bending without losing the function and quality of the material. On the battens, a full planking (tongue-and-groove) 2.5 cm thick is laid transversely. This is followed by a protective waterproofing membrane and the grooved roofing material Prefalz. The final white shade was chosen considering both functionality and aesthetics. The rougher surface, known as stucco, ensures originality and reduced noise during rain.

The most optimal covering method chosen was simple horizontal seams on the flat area and double seaming at the corners. The cylindrical area of the retractable gates posed a challenge for the roofing. The zero and negative slope at the top of the gates was a critical point, and choosing a different covering method sparked debates about the final impression. Ultimately it was decided on continuous seams from top to bottom, requiring mechanical profiling and rolling into the desired radius of 2800 mm over a length of 5850 mm. The rolling took place directly on site. “We utilized the excellent service of PREFA Aluminiumprodukte. Thanks especially to Mr. Roman Vaňka for his willingness and dedication. We scheduled a date for May 15, 2014, and despite the very windy and uncertain weather that prevailed on that day, he arrived at the agreed hour with the RBM bending machine from Schlebach directly on site. On the "pampered" lawn of the investor's garden, we then "drew" the required arc with lime, and practically within 1 hour we had the roofing ready for installation. The final result is more than satisfactory,” specifies the roofer Jan Pavel.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment