The new ski service in the village of Pstruží was built in a very short time by the company RD Rýmařov

On the walls and floors, fermacell gypsum fiber boards are used.

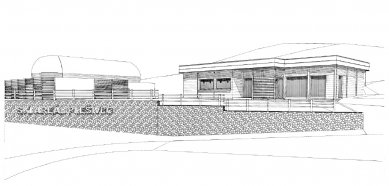

In October 2012, the long-awaited Plešivec ski resort in the Ore Mountains began construction. The resort was built from the ground up, and its first visitors were welcomed by the investor and operator, HR Agency s.r.o., in December 2013. From November to December of last year, the construction was also supported by RD Rýmařov, which built a new ski service in the village of Pstruží near Merklín (Karlovy Vary District).

The construction of the Plešivec ski resort represented a unique project in Europe for a ski area, and the entire construction was divided into three phases. The first phase was delivered for the investor by the consortium Strabag a.s. - Leitner Group, which won the tender.

The first phase included the construction of three cable cars, downhill runs with snowmaking, pump stations and cooling towers, lighting for the slopes, the creation of parking facilities in the village of Pstruží, social facilities, and a ticketing and information system. During the second phase, additional downhill runs were built, a ski and children's park was established, including moving walkways and lifts. Additional parking and facilities with rentals and professional service for skis and snowboards arose in the cadastre of Pstruží. Both phases were completed in December 2013. The third and final phase will be completed during the summer of 2014. The new Plešivec ski area is the youngest and one of the most beautiful ski resorts in the Czech Republic. Thanks to modern technologies, it offers artificial snowmaking, fast and comfortable lifts, over 10 km of slopes, a ski service, ski school, and quality refreshments throughout the area.

The new ski service from RD Rýmařov is located at the foot of Plešivec at an altitude of 708 m above sea level, and was designed by Architect Břetislav Kubíček and designer Michal Jung from Karlovy Vary. The building, with a footprint of 370 m², was constructed during November and December 2013 for 12 million CZK and serves the new ski area as a service point, rental, and facility for the ski school. The building includes a ticket office and restrooms for visitors. In terms of building materials used, the building represents a combination of concrete foundation, steel framework, and wood. The roof of the ski service is a shed type with a minimal slope and overhangs on all sides. The building, which has one above-ground floor, is spaced out into three areas:

- the ski service area, which functions as an open space hall with separate sections; the only enclosed part is the service workshop, behind which rooms for the technical facilities of the building are located,

- the area for ticket offices and staff facilities, accessible through the ski service,

- the restroom area for visitors, including a WC for disabled persons.

The building is barrier-free and allows persons with disabilities to move freely inside without any restrictions.

Fermacell fiber cement materials are used for the floors and walls of the new ski service.

The combination of Fermacell 2E22 flooring elements and 15 mm cement fiberboard Fermacell Powerpanel H2O was chosen for the high resistance of the Fermacell cement fiberboards to moisture – water and snow on the ski service floor are unavoidable. To drain water, four Fermacell Powerpanel TE drainage systems, measuring 1000 x 1000 mm, are installed in the floor.

Wall Structure (from Exterior to Interior):

The construction of the Plešivec ski resort represented a unique project in Europe for a ski area, and the entire construction was divided into three phases. The first phase was delivered for the investor by the consortium Strabag a.s. - Leitner Group, which won the tender.

The first phase included the construction of three cable cars, downhill runs with snowmaking, pump stations and cooling towers, lighting for the slopes, the creation of parking facilities in the village of Pstruží, social facilities, and a ticketing and information system. During the second phase, additional downhill runs were built, a ski and children's park was established, including moving walkways and lifts. Additional parking and facilities with rentals and professional service for skis and snowboards arose in the cadastre of Pstruží. Both phases were completed in December 2013. The third and final phase will be completed during the summer of 2014. The new Plešivec ski area is the youngest and one of the most beautiful ski resorts in the Czech Republic. Thanks to modern technologies, it offers artificial snowmaking, fast and comfortable lifts, over 10 km of slopes, a ski service, ski school, and quality refreshments throughout the area.

The new ski service from RD Rýmařov is located at the foot of Plešivec at an altitude of 708 m above sea level, and was designed by Architect Břetislav Kubíček and designer Michal Jung from Karlovy Vary. The building, with a footprint of 370 m², was constructed during November and December 2013 for 12 million CZK and serves the new ski area as a service point, rental, and facility for the ski school. The building includes a ticket office and restrooms for visitors. In terms of building materials used, the building represents a combination of concrete foundation, steel framework, and wood. The roof of the ski service is a shed type with a minimal slope and overhangs on all sides. The building, which has one above-ground floor, is spaced out into three areas:

- the ski service area, which functions as an open space hall with separate sections; the only enclosed part is the service workshop, behind which rooms for the technical facilities of the building are located,

- the area for ticket offices and staff facilities, accessible through the ski service,

- the restroom area for visitors, including a WC for disabled persons.

The building is barrier-free and allows persons with disabilities to move freely inside without any restrictions.

Fermacell fiber cement materials are used for the floors and walls of the new ski service.

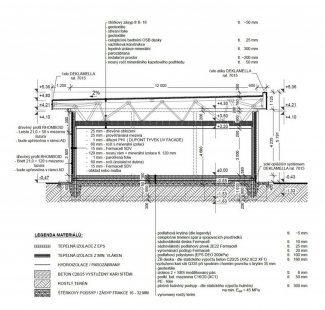

Floor Structure:

| floor covering - Forbo linoleum or carpet (in the store) |

~ 5 mm |

| Fermacell Powerpanel H2O fiber cement board | 12.5 mm |

| Fermacell 2E22 fiber cement flooring element | 25 mm |

| Fermacell leveling underlayment | 20 mm |

| floor polystyrene (EPS DEO 200kPa) | 100 mm |

| Reinforced concrete slab (reinforced with Q335 mesh at both the bottom and top surface with 35 mm coverage) |

160 mm |

| geotextile | |

| insulation 2 × SBS modified bitumen membrane | 8 mm |

| underlayment concrete screed C16/20 (XC1) | 50 mm |

| PE - foil | |

| compacted subbase - compacted according to static calculations | 300 mm |

The combination of Fermacell 2E22 flooring elements and 15 mm cement fiberboard Fermacell Powerpanel H2O was chosen for the high resistance of the Fermacell cement fiberboards to moisture – water and snow on the ski service floor are unavoidable. To drain water, four Fermacell Powerpanel TE drainage systems, measuring 1000 x 1000 mm, are installed in the floor.

Wall Structure (from Exterior to Interior):

| wooden cladding | 25 mm |

| ventilated gap | 25 mm |

| diffusion facade membrane DuPont Tyvek UV Facade | 1 mm |

| frame with mineral insulation | 60 mm |

| Fermacell fiber cement board | 15 mm |

| load-bearing frame + mineral insulation | 120 mm |

| vapour barrier foil | 1 mm |

| frame (installation cavity) |

60 mm |

| Fermacell fiber cement board | 15 mm |

| cladding or painting |

|

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment

Related articles

0

27.05.2014 | New kindergartens made from Fagus modules are springing up like mushrooms after rain in Germany following last year's change in the law

0

22.04.2014 | New modular facilities for KOMA MODULAR employees with fermacell materials on ceilings, walls, and floors

0

18.03.2014 | When riding the new cable car to Sněžka, you can't miss the fermacell boards

1

05.03.2014 | Family housing on the roof of the shopping center was created thanks to the lightweight steel structure Lindab and fermacell boards