Hotel Bartoš has received a new look and a powerful solar power plant

Hotel Bartoš is located in the west of Frenštát pod Radhoštěm, on the very edge of the Beskydy Mountains. The town is the birthplace of the famous ski jumper and Olympic champion from 1968, Jiří Raška, as evidenced by the two ski jumps standing nearby. The original rectangular-structured building was built in the 1970s as a longitudinal load-bearing system with a flat roof. After the revolution, it gained a new owner who decided to give the building a new face.

The most significant changes involved the roof and a new shelter for car parking. The existing flat roof was redesigned into a shed roof with a slope of 10°. Both longitudinal sides transition smoothly into the facade with an arch. The termination of the facade at the last floor's level ends in a rectangular cornice gutter. The roof of the parking area adjacent to the ground floor of the hotel is also a shed roof with a minimal slope. The proposed material was folded sheet metal in a color resembling weathered copper. Besides the requirements for high quality and long-lasting durability, the investor was interested in how all important details would be executed. Explaining the technical process and seeing it with one's own eyes are, however, two completely different matters. Thus, PREFA Aluminiumprodukte suggested to Mr. Bartoš the option to visit another construction of a similar type, which was being completed at that time in the Beskydy Mountains.

The family house of atypical shapes immediately caught attention with its numerous complex plumbing details and the precision of the work done. The exceptional appearance and workmanship significantly assisted Mr. Bartoš in choosing the material and a quality plumbing company. The realization heading into the winter months provided the final reason for choosing PREFALZ aluminum sheet in patina green, with plumbing by Antonín Ondrůšek becoming the main contractor for the project. Thanks also go to the boys from Jiří Raška's company, the son of the now legendary ski jumper.

The roof reconstruction began in September of last year. After the framing of the shed and arches, IKO strips were laid on an asphalt base with a thickness of 0.6 mm. The folded covering was divided into 5 segments – roof, arches, and facade. Measuring the individual seams and projecting them onto the facade was very important due to the existing windows. The main longest strips transition smoothly into the arch, which ends at the window lintel or continues around the reveal into the rectangular gutter. The arches were rounded according to the existing radius. The roofing strips are joined with a double standing seam and filled with folding gel. The facade is created with an angular groove. All material is anchored with stainless fasteners and screws into the formwork. Expansion is addressed with transverse sliding overlaps and appropriate distribution of fixed and movable fasteners.

Photovoltaic Power Plant

As is often the case today, every property owner's aim is to minimize operating costs. The price of energy is constantly rising, which most affects large properties serving the public. Mr. Bartoš also contemplated a photovoltaic power plant in the project. Thinking about the future is very important in any field, and installing an alternative energy source for the hotel certainly belongs to that. The roof slope of 10° and the building's orientation to the south further supported this decision.

There are many manufacturers of photovoltaic systems, but when you need to integrate the system into folded roofing without interrupting the expansion and simultaneously receiving all warranties, the circle of suppliers shrinks significantly. A high performance guarantee for 25 years and a price comparable to competitors ultimately convinced the investor to implement the PREFA PS.13 photovoltaic system. This allows for the connection of all components up to the distribution board. The entire implementation is preceded by an accurate calculation simulating the distribution of the supporting structure depending on the snow load and determining the maximum area of installed power. In our case, it was 30 kWp.

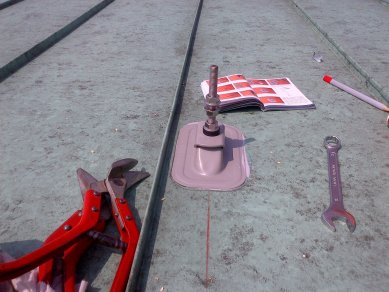

The foundation of the installation consists of a load-bearing aluminum structure, which is supported by PREFA Sunny solar holders screwed into the rafter. Their shape and special composition do not hinder material movement due to thermal expansion. An oval hole 40 mm long is cut into the sheet, and its edges are raised by 10 mm all around. This ensures that moisture that enters beneath the holder's cover does not get into the roof space. A screw is anchored in the rafter, and the holder's cover is then glued with a special set directly onto the sheet. Aluminum braces that form the supporting grid for the photovoltaic panels are connected to the solar holders. The entire PS.13 system includes complete installation into the roof structure, E2000 photovoltaic panels, Fronius inverters, and cabling ending at the distribution board.

Despite unpleasant delays caused by energy authorities, the photovoltaic system was successfully connected during October. The ongoing interior renovation and the newly built parking area will be completed in 2014.

Construction Data:

Location: Frenštát pod Radhoštěm

Object: Hotel Bartoš

Construction: 2013–2014

Area: roof area: 900 m2

Architect: Ing. arch. Stibora Petr

Installation Company: plumbing by Antonín Ondrůšek

Product Range PREFA PREFALZ – rolled sheet:

Brief description: Color rolled aluminum sheet is predestined for individual and creative solutions for roofs and facades due to its excellent folding quality and surface treatment.

Material: Alloyed aluminum with a thickness of 0.7 mm with a high-quality two-layer baked enamel, weight 2.2 kg/m2. The material is malleable and very resistant to all weather conditions. It can be laid from 3 °.

Roll dimensions: thickness: 0.7 mm, width: 500/650/1000 mm

Colors: 15 standard colors, upon request all RAL, NCS colors, smooth or stucco surface finish, a protective film can also be supplied for the smooth surface.

|

The most significant changes involved the roof and a new shelter for car parking. The existing flat roof was redesigned into a shed roof with a slope of 10°. Both longitudinal sides transition smoothly into the facade with an arch. The termination of the facade at the last floor's level ends in a rectangular cornice gutter. The roof of the parking area adjacent to the ground floor of the hotel is also a shed roof with a minimal slope. The proposed material was folded sheet metal in a color resembling weathered copper. Besides the requirements for high quality and long-lasting durability, the investor was interested in how all important details would be executed. Explaining the technical process and seeing it with one's own eyes are, however, two completely different matters. Thus, PREFA Aluminiumprodukte suggested to Mr. Bartoš the option to visit another construction of a similar type, which was being completed at that time in the Beskydy Mountains.

The family house of atypical shapes immediately caught attention with its numerous complex plumbing details and the precision of the work done. The exceptional appearance and workmanship significantly assisted Mr. Bartoš in choosing the material and a quality plumbing company. The realization heading into the winter months provided the final reason for choosing PREFALZ aluminum sheet in patina green, with plumbing by Antonín Ondrůšek becoming the main contractor for the project. Thanks also go to the boys from Jiří Raška's company, the son of the now legendary ski jumper.

The roof reconstruction began in September of last year. After the framing of the shed and arches, IKO strips were laid on an asphalt base with a thickness of 0.6 mm. The folded covering was divided into 5 segments – roof, arches, and facade. Measuring the individual seams and projecting them onto the facade was very important due to the existing windows. The main longest strips transition smoothly into the arch, which ends at the window lintel or continues around the reveal into the rectangular gutter. The arches were rounded according to the existing radius. The roofing strips are joined with a double standing seam and filled with folding gel. The facade is created with an angular groove. All material is anchored with stainless fasteners and screws into the formwork. Expansion is addressed with transverse sliding overlaps and appropriate distribution of fixed and movable fasteners.

Photovoltaic Power Plant

As is often the case today, every property owner's aim is to minimize operating costs. The price of energy is constantly rising, which most affects large properties serving the public. Mr. Bartoš also contemplated a photovoltaic power plant in the project. Thinking about the future is very important in any field, and installing an alternative energy source for the hotel certainly belongs to that. The roof slope of 10° and the building's orientation to the south further supported this decision.

There are many manufacturers of photovoltaic systems, but when you need to integrate the system into folded roofing without interrupting the expansion and simultaneously receiving all warranties, the circle of suppliers shrinks significantly. A high performance guarantee for 25 years and a price comparable to competitors ultimately convinced the investor to implement the PREFA PS.13 photovoltaic system. This allows for the connection of all components up to the distribution board. The entire implementation is preceded by an accurate calculation simulating the distribution of the supporting structure depending on the snow load and determining the maximum area of installed power. In our case, it was 30 kWp.

The foundation of the installation consists of a load-bearing aluminum structure, which is supported by PREFA Sunny solar holders screwed into the rafter. Their shape and special composition do not hinder material movement due to thermal expansion. An oval hole 40 mm long is cut into the sheet, and its edges are raised by 10 mm all around. This ensures that moisture that enters beneath the holder's cover does not get into the roof space. A screw is anchored in the rafter, and the holder's cover is then glued with a special set directly onto the sheet. Aluminum braces that form the supporting grid for the photovoltaic panels are connected to the solar holders. The entire PS.13 system includes complete installation into the roof structure, E2000 photovoltaic panels, Fronius inverters, and cabling ending at the distribution board.

Despite unpleasant delays caused by energy authorities, the photovoltaic system was successfully connected during October. The ongoing interior renovation and the newly built parking area will be completed in 2014.

Construction Data:

Location: Frenštát pod Radhoštěm

Object: Hotel Bartoš

Construction: 2013–2014

Area: roof area: 900 m2

Architect: Ing. arch. Stibora Petr

Installation Company: plumbing by Antonín Ondrůšek

Product Range PREFA PREFALZ – rolled sheet:

Brief description: Color rolled aluminum sheet is predestined for individual and creative solutions for roofs and facades due to its excellent folding quality and surface treatment.

Material: Alloyed aluminum with a thickness of 0.7 mm with a high-quality two-layer baked enamel, weight 2.2 kg/m2. The material is malleable and very resistant to all weather conditions. It can be laid from 3 °.

Roll dimensions: thickness: 0.7 mm, width: 500/650/1000 mm

Colors: 15 standard colors, upon request all RAL, NCS colors, smooth or stucco surface finish, a protective film can also be supplied for the smooth surface.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment