|

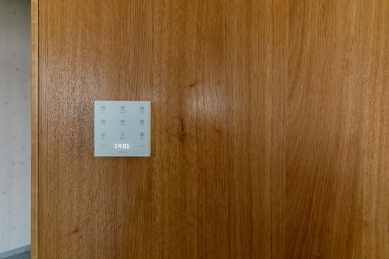

The century-old building at Lazebnická 3 in the center of Opava has undergone a renaissance thanks to a sensitive reconstruction that utilized wood as the main building material. This house now draws attention not only for its rich and tumultuous history. This year, a wooden extension was added to it, which serves as a model for Prague and other cities regardless of their size.