<ProductLifeCycle>Pergo Vinyl</ProductLifeCycle>

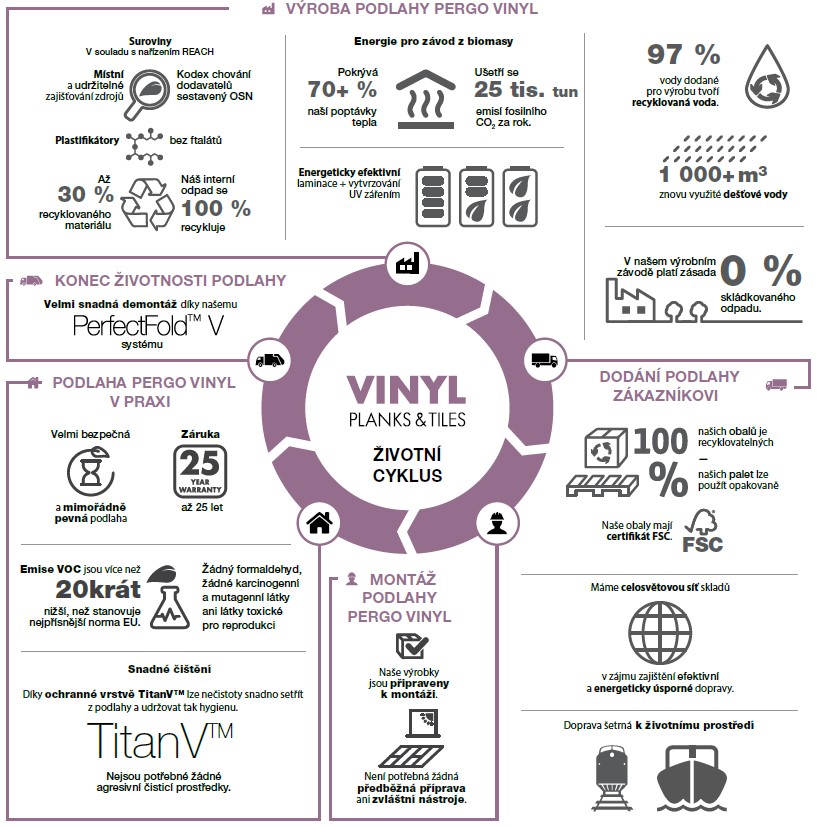

Pergo is committed to reducing its ecological footprint and helping its customers do the same. The main priority at each stage of the Pergo Vinyl flooring lifecycle is sustainability. From procurement and manufacturing to distribution, during the flooring's lifespan until its end, we strive to enhance the energy efficiency of our processes and minimize our impact on the environment.

Manufacturing Pergo Vinyl

|

The LVT manufacturing plant focuses primarily on incorporating renewable energy and striving for energy efficiency at every step of production.

Raw Materials

Our commitment to reducing our ecological footprint starts with sustainably sourcing raw materials. The Pergo Vinyl product is made from PVC, fillers, additives, and plasticizers. All these components are 100% virgin raw materials upon delivery to the manufacturing plant. All raw materials are thoroughly checked, and our binding Supplier Code of Conduct, based on the 10 principles of the UN Global Compact, ensures the sustainable and socially responsible sourcing of these materials. Additionally, all raw materials comply with the REACH regulation (REACH is a European Union regulation aimed at improving the protection of human health and the environment from risks posed by chemicals).

Plasticizers are used in LVT to achieve the flexibility of the planks. Their impact on human health is a topic of discussion. Specifically, phthalates pose health risks. Therefore, we do our work without them. We were among the first companies to launch phthalate-free vinyl flooring. We exclusively use DOTP, which is the same type of plasticizer allowed in children's toys or food packaging. This 100% guarantee of using DOTP is also why we do not recycle external vinyl waste.

However, this does not mean that Pergo does not recycle at all. All our internally generated manufacturing waste (trimmings, rejects, sawdust, and sandblasting dust...) is 100% recycled and used in our products.

Water Supply and Waste Management

The water used in our facilities is mainly for heating and cooling during production. Water management and protection of water resources are among the main pillars of environmental conservation worldwide. Pergo recognizes this fact and has taken several measures to reduce water consumption during production and prevent wastewater generation. We can confidently state that 97% of the water supplied for production comes from internally recycled water. Additionally, 1,000 m³ of rainwater is utilized. We aim not only to prevent the generation of wastewater but also to eliminate the creation of waste at work by optimizing recycling procedures, which includes recycling 100% of manufacturing waste. We guarantee that no waste leaves our manufacturing plant to go to landfills.

Transport and Distribution

|

Our commitment to sustainability does not end when the product leaves the factory premises. We are well aware of the issues caused by the global transport sector, such as high energy consumption, health issues related to air quality, packaging waste, traffic congestion... Therefore, we continually seek alternative ways to supply goods to our customers.

Packaging

Eco-friendly green transport of flooring to the customer begins with the packaging of the product. Pergo Vinyl flooring packaging is 100% recyclable and has FSC certification. Pallets can also be reused 100%.

Distribution Network

We have a global network of warehouses for a wide range of Pergo products to ensure efficient and energy-saving transportation. With warehouses and distribution centers in Belgium, the United Kingdom, Sweden, France, Poland, Ukraine, Russia, and the United States, we can combine product transportation and avoid poorly optimized transportation.

Alternative Transportation Methods

Since trucks represent a carbon-intensive mode of transportation, we invest in alternative transport methods, such as terminals linked to inland waterways, intermodal freight transport, and short-sea shipping.

• Terminals linked to inland waterways: the Pergo manufacturing plant is located close to the Leie River,

allowing us to transport goods to national ports via inland waterways.

• Intermodal freight transport: for deliveries of Pergo Vinyl flooring to Italy and Scandinavian countries, we use two modes of freight transport: trucks and rail.

• Short-sea shipping to Scandinavia and Russia: cargo is transported mainly

by coastal cargo ships.

Installation of Pergo Vinyl Flooring

Installing Pergo Vinyl flooring is very quick and easy. Our products don't need pre-installation preparation – they are ready for immediate use. They can be easily cut with a curved laminate knife. No special tools are required.

Enjoying Pergo Vinyl Flooring at Home

|

Extremely Low VOC and No Harmful Substances

Choosing Pergo Vinyl flooring is choosing a healthy floor. Thanks to the fully sealed surface of LVT flooring, extremely minimal amounts of volatile organic compounds (VOCs) are released. VOCs are substances that affect indoor air quality. The total amount of VOCs emitted by Pergo Vinyl flooring is 50 times lower than the applicable strictest EU standard. As a result of this fact, we have obtained the following certifications:

• U-zeichen DIBt approval. DIBt is the German Institute for Civil Engineering that establishes health

quality standards for products intended for internal use and promotes the development of products with particularly low emissions.

• In France, product testing is conducted using a testing method in accordance with ISO 16000, assessing the emission behavior regarding VOC. All our LVT floor coverings have received the highest rating of A+, indicating that emissions are very low.

• M1: Finnish construction emissions: the aim of the classification is to improve the development and use of low-emission construction

materials so that material emissions do not increase ventilation requirements. Additionally, our products contain no formaldehyde or carcinogenic, mutagenic, or reprotoxic substances classified as 1A and 1B (a list of potential substances). Pergo Vinyl flooring contains no heavy metals, lead/cadmium. As mentioned above, our products do not contain harmful plasticizers.

Hygienic Benefits

The main advantages of Pergo Vinyl flooring are its solid surface layer and highly protective PU coating. Thanks to these two fundamental properties, our vinyl flooring is perfectly suited for high-traffic rooms and areas. The perfectly sealing surface of Pergo Vinyl flooring helps maintain hygiene. It prevents the accumulation of bacteria and dirt, which can be easily wiped away. Therefore, you do not need to use aggressive cleaning agents when cleaning.

End of Flooring Life

The easy-to-use Perfect Fold V click system allows for easy disassembly of the flooring and its reuse in another location. After the end of its life, the waste flooring can be recycled into new products (depending on the local situation). Information about local recycling programs in your area can be provided by your local retailer/waste recycling facility.