What should decide on the proper selection of a window?

DECEPTIVE INFORMATION OR REAL QUALITY?

Builders, window suppliers, investors, but also the general and professional public are unfortunately still confronted with misleading information regarding the quality of windows and their selection. In many cases, there is a misinterpretation of the technical properties of windows, which can lead to certain companies being excluded from selection procedures or public tenders for window suppliers in advance. This is despite the fact that the guidelines of the Czech Chamber of Lightweight Facades highlight this issue and very clearly specify the method for assessing the quality of the window as a whole. It is possible that this happens sometimes intentionally, and other times out of ignorance. The entire issue has several levels.

A few more interesting facts to conclude. One of the reputable manufacturers of window profiles is REHAU, which is not only among the pioneers in the development of plastic windows but also a key promoter of sustainable practices. The proportion of recyclate in EcoPuls profiles (designation of profiles made from recyclate) ranges from 45 to 75%. This includes profiles like GENEO, SYNEGO, and BRILLANT. Thanks to this, 97 thousand tons of CO2 emissions are saved annually, which corresponds to approximately 7.8 million trees in the forest. The production of PVC profiles from first plastic burdens the environment up to 15 times more than the production of PVC from recyclate. REHAU processes over 70 thousand tons of old material annually, and PVC from window profiles can be used up to 7 times while maintaining identical quality. With a technological service life of windows of 30 years, it can be said with exaggeration that the basic raw material for window production is eternal.

www.rehau.cz

First Misunderstanding – The Number of Chambers Decides

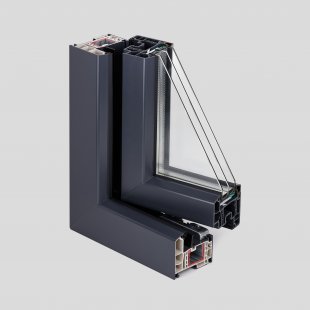

Despite ongoing education, we can still witness erroneous arguments based on historical realities from the early 1990s. Specifically, we are talking about the number of chambers in the window profile, the construction depth of the frame and sash measured in mm, and not least the classification of the profile into classes A, B, C. First, it should be said that in terms of thermal insulation properties of the window, the number of chambers or its construction depth is not decisive in any case. The main and therefore sufficiently indicative parameter in this regard is the heat transfer coefficient of the window as a whole Uw (i.e., including glazing and any fillings of the chambers). The Czech standard has so far established a minimum recommended value of Uw = 1.2 W/m²K for rooms with a design temperature of 18 to 22 °C. Practices show that the most commonly used window profiles have a construction depth of 80 mm. For example, we can mention REHAU's SYNEGO profile, which can achieve a Uw value of 0.63 W/m²K with triple glazing.Second Misunderstanding – Profile Class A is Better than B

Discrimination against certain profiles occurs during the announcement of a tender when a specific profile class is recommended or even prescribed. Let us recall that the profile class according to standard EN 12608 classifies window profiles into classes A, B, and C based on the profile thickness. Specifically, in class A, profiles have a thickness of ≥ 2.8 mm, while in class B, profiles have a thickness of 2.5 to 2.79 mm. However, no class conveys anything about the quality of the window because nowhere is it written that greater thickness means higher quality. Let's consider a similar parallel in metallurgy. After all, there are several categories of structural steels, and everyone knows that higher quality steel can produce thinner sheets that will be stronger than thicker sheets made from lower quality steel. And this is exactly the case with the production of window profiles. Why does the misunderstanding occur? Previously, practically all profiles were manufactured with a construction depth of 60 mm. At that time, practical tests of welds in corner joints proved that the thinning of the profile results in reduced strength of the welded areas. However, over the last 25 years, both the manufacturing technology of PVC, which is much more advanced than before, and the construction depth (80 or 86 mm) have changed. The greater the construction depth of the profile, the logically greater the welded area in the corner, and thus its strength increases, along with improvements in the overall stiffness of the window. Moreover, from the science of technology, it follows that other factors, such as the incorrect angle of the cutting saw, the perpendicularity of the cut, poorly set welding temperature, uncleaned material, etc., influence the strength of corner welds. It is also worth mentioning that, for example, the prescribed strength value of the corner weld (4400 N) for the given type of PVC profile is easily met by profiles of classes A and B, as the actual strength values in both cases are close to 6000 N. It is therefore clear that it is not the class, but the quality of manufacturing and the PVC formula that are decisive. And even if nothing else matters, it is essential that the window meets the required construction parameters according to the technical standard for windows and doors ČSN EN 14351-1+A2.Third Misunderstanding – Recyclate Deteriorates Window Properties

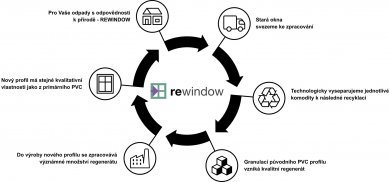

Environmental protection is one of the main priorities of every developed society. Therefore, sustainability is also a major topic among PVC window profile manufacturers. In this context, there is again a distortion of some facts. First, it should be said that modern plastic windows exhibit such extremely low heat transfer coefficients that they significantly contribute to reducing the energy losses of buildings. That is their great plus. In addition, it is necessary to mention that the construction industry in the EU contributes significantly to the overall waste production (25 to 30%). For this reason, the effort to maximize the recycling of materials, including PVC, which is incidentally 100% recyclable, is growing. Therefore, the replacement of an old plastic window with a new one does not generally increase the volume of waste produced. However, there are false statements that recyclate deteriorates the technical and physical properties of the window, especially its strength. In fact, it is the opposite. Tests have shown that the strength of the welds improves by about 17%. The question is, who says that this is not the case when all reputable manufacturers and suppliers of PVC profiles are united in the Rewindo association and thus committed to successful recycling of the primary material? In some EU countries, a proportion of recycled materials (up to 20%) is even prescribed. The co-extrusion process (multi-layer extrusion) combines the best properties of both materials into one compact entity. Only those areas of the profile that are visible are covered with first plastic since the regenerant is not 100% white. The percentage of first plastic logically depends on the profile construction. From this, it follows that the main aspect is the quality of the PVC manufacturing formula.A few more interesting facts to conclude. One of the reputable manufacturers of window profiles is REHAU, which is not only among the pioneers in the development of plastic windows but also a key promoter of sustainable practices. The proportion of recyclate in EcoPuls profiles (designation of profiles made from recyclate) ranges from 45 to 75%. This includes profiles like GENEO, SYNEGO, and BRILLANT. Thanks to this, 97 thousand tons of CO2 emissions are saved annually, which corresponds to approximately 7.8 million trees in the forest. The production of PVC profiles from first plastic burdens the environment up to 15 times more than the production of PVC from recyclate. REHAU processes over 70 thousand tons of old material annually, and PVC from window profiles can be used up to 7 times while maintaining identical quality. With a technological service life of windows of 30 years, it can be said with exaggeration that the basic raw material for window production is eternal.

www.rehau.cz

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment