Tobacco Factory in Linz

Tobacco Factory Linz

The third largest Austrian city experienced a boom during the Industrial Revolution in the 19th century, primarily due to its good connection to water and railway transport. In addition to factories producing steel and textiles, the tobacco processing industry also settled in Linz. The monopoly on the processing and sale of tobacco in the Austrian Empire was guaranteed by the general patent of Emperor Leopold issued in 1701, allowing the first tobacco manufactories to emerge from 1723. A second patent from Joseph II further strengthened regulation by establishing central oversight over the import, production, and sale of tobacco. The three existing factories in 1850 were joined by a production facility in Linz in the former complex of a wool processing and carpet manufacturing factory, which had been established in 1668 near the historic center of Linz on the banks of the Danube but had to close due to strong competition from Czech textile factories, replaced by tobacco processing. Initially, the manufactory operated in modest conditions under military administration, but after nine years (in 1859), the factory employed over a thousand workers and underwent continuous expansion and modernization (in 1870, 1880, 1903, 1913, and 1918).

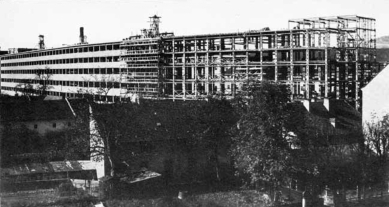

In 1928, production rose to 1.5 billion cigarettes, 1.5 million kilograms of pipe tobacco, and 750,000 kilograms of cigarette tobacco. This necessitated modernization, which was no longer feasible within the existing buildings. Professor Peter Behrens from the Vienna Academy and his assistant Alexander Popp were commissioned to develop a project for a new factory in 1928. Construction began a year later at the least opportune time, as the world economic crisis peaked, leading to continuous budget cuts and prolonged construction duration. The factory was ultimately completed thanks largely to the then Minister of Finance Karl Buresch.

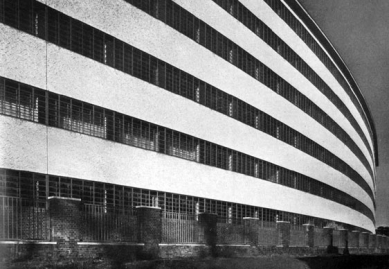

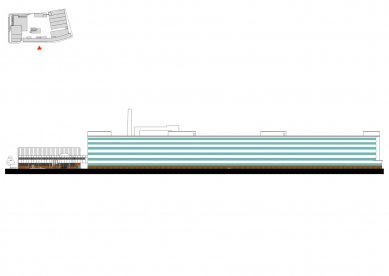

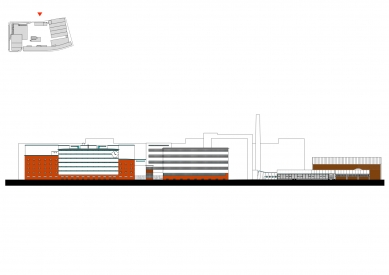

The resulting nearly quarter-kilometer-long building in international style is the result of rational considerations regarding construction and the most efficient internal operations. The steel skeleton, weighing only 3,000 tons, was subsequently enclosed for fire safety reasons. The turquoise color used for the paint on the steel windows and doors has led to the term "Linz blue." Maintaining a constant temperature, humidity, and good lighting conditions was necessary for cigarette production, which was sufficiently taken care of by the strip windows.

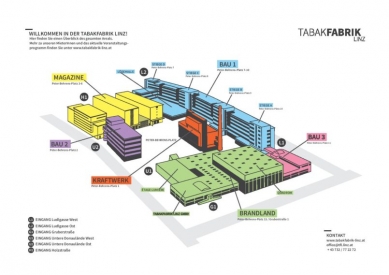

With the end of the Austro-Hungarian monarchy, the company was renamed Austria Tabak, which was subsequently bought by Japan Tobacco International; however, due to the global campaign against the tobacco industry, production at the Linz site was terminated in September 2009. The city of Linz bought the factory back and now offers the four-hectare site with eight hectares of usable space for various start-up companies and creative professions.

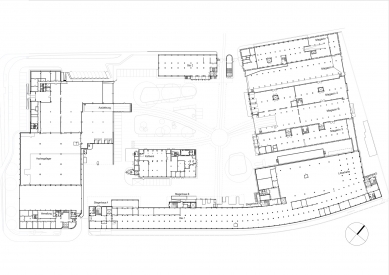

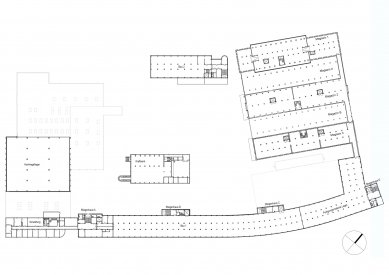

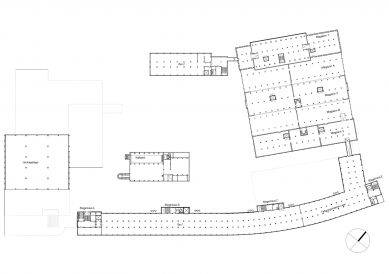

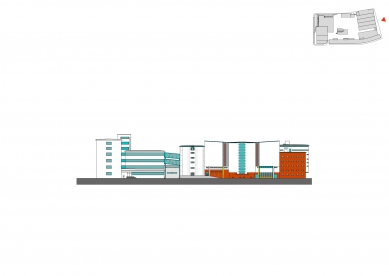

After the archetypal AEG building in Berlin and the expressionist Hoechst factory in Frankfurt, this is the last industrial building designed by Behrens. In 1981, the factory was declared an industrial monument, and in February 2018, the results of an architectural competition for the completion of the western part of the production facility were announced, where new administrative towers are to be built according to the winning project by Zechner&Zechner.

In 1928, production rose to 1.5 billion cigarettes, 1.5 million kilograms of pipe tobacco, and 750,000 kilograms of cigarette tobacco. This necessitated modernization, which was no longer feasible within the existing buildings. Professor Peter Behrens from the Vienna Academy and his assistant Alexander Popp were commissioned to develop a project for a new factory in 1928. Construction began a year later at the least opportune time, as the world economic crisis peaked, leading to continuous budget cuts and prolonged construction duration. The factory was ultimately completed thanks largely to the then Minister of Finance Karl Buresch.

The resulting nearly quarter-kilometer-long building in international style is the result of rational considerations regarding construction and the most efficient internal operations. The steel skeleton, weighing only 3,000 tons, was subsequently enclosed for fire safety reasons. The turquoise color used for the paint on the steel windows and doors has led to the term "Linz blue." Maintaining a constant temperature, humidity, and good lighting conditions was necessary for cigarette production, which was sufficiently taken care of by the strip windows.

With the end of the Austro-Hungarian monarchy, the company was renamed Austria Tabak, which was subsequently bought by Japan Tobacco International; however, due to the global campaign against the tobacco industry, production at the Linz site was terminated in September 2009. The city of Linz bought the factory back and now offers the four-hectare site with eight hectares of usable space for various start-up companies and creative professions.

After the archetypal AEG building in Berlin and the expressionist Hoechst factory in Frankfurt, this is the last industrial building designed by Behrens. In 1981, the factory was declared an industrial monument, and in February 2018, the results of an architectural competition for the completion of the western part of the production facility were announced, where new administrative towers are to be built according to the winning project by Zechner&Zechner.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment