Schlumberger Research Centre

Phase I 1982-85

Single-storey winged buildings for scientific studies and laboratories flanking the test drilling station and social facilities under a translucent membrane roof.

Awards: RIBA National Awards for Architecture 1988, Civic Trust Award 1988, Financial Times Architecture Award 1985, Structural Steel Award 1988

Phase II 1990-92

Two free-standing pavilion buildings housing offices, laboratories, and computer workspaces are connected by a translucent membrane roof covering a new entry hall.

Awards: RIBA National Awards for Architecture 1993, Financial Times finalist 1993

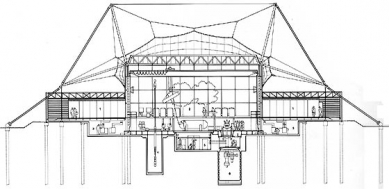

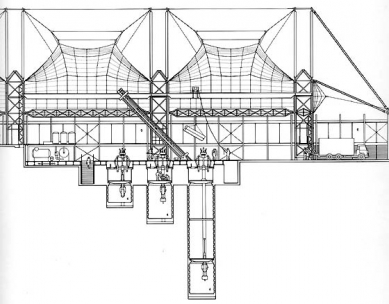

The building, completed in 1984, is located west of Cambridge. It is an interesting example of the use of Teflon-coated glass cloth. The shape of the building results from its function as a testing facility for oil drilling and the desire for close contact between scientists from different fields. The central nave consists of three 24x18 meter large sections. To the west and east, it divides into five offices. Between the segments are the entrances. The buildings utilize the topography of the surroundings: the testing hall is located 2.5 meters below the offices and the main entrance. In the southern part, there is a winter garden with a cafeteria and a library. The office naves: each nave consists of five elements built on Hopkins's Patera system. Each segment consists of 5 offices with a module of 3.6 meters. The roof structure (span of 13.2 meters) supports the suspended roof envelope. The exterior walls of the offices consist of double-glazed 3-meter-high sliding doors made of insulating double glazing. The four-walled sections of the office wings are made of insulating panels. The ceiling made of shaped steel sheets acts as a stiffening element. The floor consists of sandwich panels. The glass interior walls are soundproof due to noise from the testing drills. Except for the foundations, the entire building was assembled from prefabricated parts using dry methods. Structural framework: The roof envelope is suspended on cables, which are attached to an external steel structure. The main components of this system are truss towers with a module of 19.2 meters. In the longitudinal direction, the frames are reinforced by a framed truss structure. The roof envelope consists of translucent Teflon-coated glass fibers. Teflon does not corrode and does not lose its mechanical properties due to UV radiation. Its lifespan is over 20 years. The individual edges of the cloth are folded and welded. The finished membrane is attached to the supporting cables using clamps. This allows the membrane to be easily tensioned. The engineering networks of the laboratories and offices lie in shafts below the floor. Hopkins used metal panels invented by Jean Prouvé as the envelope for his Patera system objects in this project.

Single-storey winged buildings for scientific studies and laboratories flanking the test drilling station and social facilities under a translucent membrane roof.

Awards: RIBA National Awards for Architecture 1988, Civic Trust Award 1988, Financial Times Architecture Award 1985, Structural Steel Award 1988

Phase II 1990-92

Two free-standing pavilion buildings housing offices, laboratories, and computer workspaces are connected by a translucent membrane roof covering a new entry hall.

Awards: RIBA National Awards for Architecture 1993, Financial Times finalist 1993

The building, completed in 1984, is located west of Cambridge. It is an interesting example of the use of Teflon-coated glass cloth. The shape of the building results from its function as a testing facility for oil drilling and the desire for close contact between scientists from different fields. The central nave consists of three 24x18 meter large sections. To the west and east, it divides into five offices. Between the segments are the entrances. The buildings utilize the topography of the surroundings: the testing hall is located 2.5 meters below the offices and the main entrance. In the southern part, there is a winter garden with a cafeteria and a library. The office naves: each nave consists of five elements built on Hopkins's Patera system. Each segment consists of 5 offices with a module of 3.6 meters. The roof structure (span of 13.2 meters) supports the suspended roof envelope. The exterior walls of the offices consist of double-glazed 3-meter-high sliding doors made of insulating double glazing. The four-walled sections of the office wings are made of insulating panels. The ceiling made of shaped steel sheets acts as a stiffening element. The floor consists of sandwich panels. The glass interior walls are soundproof due to noise from the testing drills. Except for the foundations, the entire building was assembled from prefabricated parts using dry methods. Structural framework: The roof envelope is suspended on cables, which are attached to an external steel structure. The main components of this system are truss towers with a module of 19.2 meters. In the longitudinal direction, the frames are reinforced by a framed truss structure. The roof envelope consists of translucent Teflon-coated glass fibers. Teflon does not corrode and does not lose its mechanical properties due to UV radiation. Its lifespan is over 20 years. The individual edges of the cloth are folded and welded. The finished membrane is attached to the supporting cables using clamps. This allows the membrane to be easily tensioned. The engineering networks of the laboratories and offices lie in shafts below the floor. Hopkins used metal panels invented by Jean Prouvé as the envelope for his Patera system objects in this project.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment