MPT Assembly Hall

The manufacturing complex of the Chrudim company TMT spol .s.r.o. is a remarkable urban and intellectual endeavor. The company converted the buildings of the former joint-stock sugar factory in Chrudim from 1867 – 1925 for its operations. During the adaptation of historic buildings, which took place from 2002 to 2007 according to a project by the Hradec Králové company ATEKO, the construction received an honorable mention in the Pardubice Region Building of the Year competition in 2008 for its concluding phase (category Buildings for Industry, Agriculture, and Water Management).

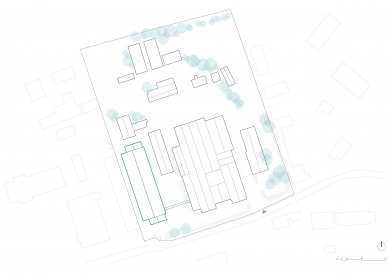

Urban Context and Architectural Concept

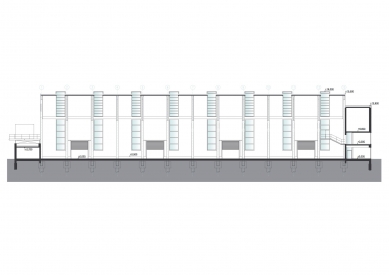

The design of the new assembly hall reflects the historical context of the joint-stock sugar factory. Using contemporary expressive means, it completes the urbanism of the manufacturing complex. Typical for the TMT complex are gables with pitched roofs and prominent vertical window openings when viewed from the street. These gables line up behind each other, creating an unmistakable layered expression of the building. Therefore, the new assembly hall is designed from the street perspective to complement the composition of the street front with two additional gables layered behind each other. The hall's ship and the front annex are in a traditional shape with a pitched roof. Vertical windows transitioning into roof skylights are inspired by the format and composition of window openings on the historic buildings of the sugar factory. The lower detached structure, covered with a semitransparent layer of perforated sheet metal, is color-matched to the aesthetics of previously reconstructed buildings. This structure houses employee facilities and comfortable meeting rooms for direct visual contact with the production area. The new spaces are connected to the existing buildings via a bridge made of a lattice steel construction that the TMT company manufactured itself. Despite all architectural and urban aspects, the entire design is guided by the demand for perfect functionality, which the operation has demonstrated.

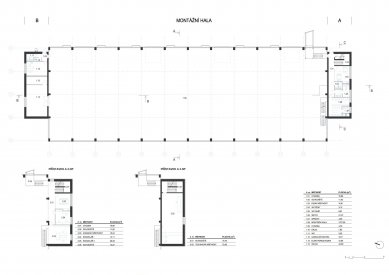

Operational Solution

The new single-nave hall serves the entire area for the final assembly of conveyors (assembly and completion of belt roller and chain conveyors). The annexes to the hall serve as operational, social, and administrative facilities. In the hall area, there are four overhead cranes with a capacity of 5 tons. The supply of parts for final assembly to the new hall is handled from other buildings in the complex by trucks or forklifts.

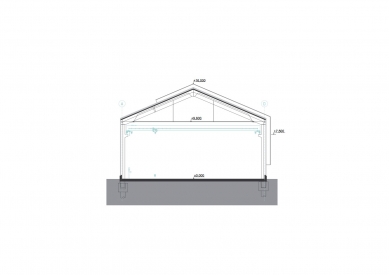

Structural and Technical Solution of the Building

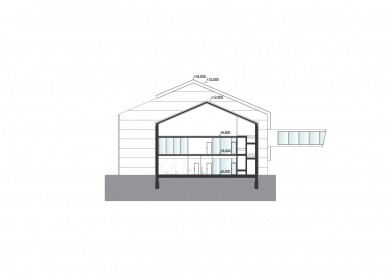

The hall section has basic dimensions of 72.64 x 24.64 m and a total height of 16.00 m, with a pitched roof with a slope of 23 degrees. Operational annexes are situated on the northern and southern sides. The annex on the northern side measures 6.15 x 17.30 m and has a flat roof with a height of 3.70 m to the parapet, used as a storage room, electrical distribution room, compressor room, and foreman's office. An HVAC unit for the hall spaces is located on the roof of the annex. On the southern side of the building, there is a three-story annex with a pitched roof with a slope of 23 degrees and a height to the ridge of the roof of 12.60 m, serving as administrative and social facilities. The floor dimensions of the annex are 6.10 x 17.20 m. On the 3rd floor, there is a technical room for housing the heating distributor, hot water tank, and HVAC unit for social facilities. The supporting structure of the hall section is prefabricated concrete. The annexes are masonry. The cladding of the assembly hall is done from sandwich panels. The front masonry annex is visually lightened and unified with a semitransparent layer of perforated sheet metal. The connecting bridge, 27.6 m long and with a profile of 2.4 x 2.9 m, is designed as a lattice steel structure clad with sandwich panels and featuring prominent horizontal glazing.

Urban Context and Architectural Concept

The design of the new assembly hall reflects the historical context of the joint-stock sugar factory. Using contemporary expressive means, it completes the urbanism of the manufacturing complex. Typical for the TMT complex are gables with pitched roofs and prominent vertical window openings when viewed from the street. These gables line up behind each other, creating an unmistakable layered expression of the building. Therefore, the new assembly hall is designed from the street perspective to complement the composition of the street front with two additional gables layered behind each other. The hall's ship and the front annex are in a traditional shape with a pitched roof. Vertical windows transitioning into roof skylights are inspired by the format and composition of window openings on the historic buildings of the sugar factory. The lower detached structure, covered with a semitransparent layer of perforated sheet metal, is color-matched to the aesthetics of previously reconstructed buildings. This structure houses employee facilities and comfortable meeting rooms for direct visual contact with the production area. The new spaces are connected to the existing buildings via a bridge made of a lattice steel construction that the TMT company manufactured itself. Despite all architectural and urban aspects, the entire design is guided by the demand for perfect functionality, which the operation has demonstrated.

Operational Solution

The new single-nave hall serves the entire area for the final assembly of conveyors (assembly and completion of belt roller and chain conveyors). The annexes to the hall serve as operational, social, and administrative facilities. In the hall area, there are four overhead cranes with a capacity of 5 tons. The supply of parts for final assembly to the new hall is handled from other buildings in the complex by trucks or forklifts.

Structural and Technical Solution of the Building

The hall section has basic dimensions of 72.64 x 24.64 m and a total height of 16.00 m, with a pitched roof with a slope of 23 degrees. Operational annexes are situated on the northern and southern sides. The annex on the northern side measures 6.15 x 17.30 m and has a flat roof with a height of 3.70 m to the parapet, used as a storage room, electrical distribution room, compressor room, and foreman's office. An HVAC unit for the hall spaces is located on the roof of the annex. On the southern side of the building, there is a three-story annex with a pitched roof with a slope of 23 degrees and a height to the ridge of the roof of 12.60 m, serving as administrative and social facilities. The floor dimensions of the annex are 6.10 x 17.20 m. On the 3rd floor, there is a technical room for housing the heating distributor, hot water tank, and HVAC unit for social facilities. The supporting structure of the hall section is prefabricated concrete. The annexes are masonry. The cladding of the assembly hall is done from sandwich panels. The front masonry annex is visually lightened and unified with a semitransparent layer of perforated sheet metal. The connecting bridge, 27.6 m long and with a profile of 2.4 x 2.9 m, is designed as a lattice steel structure clad with sandwich panels and featuring prominent horizontal glazing.

author's report

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment