RD Rýmařov built a passive house with a diffusion-open structure, which was developed based on the typical design of the Kubis Lumio house

The energy passive house with a diffusely open structure was started on Monday, November 9, 2009, by our largest manufacturer of timber constructions, RD Rýmařov. By Friday, December 18, everything was completed, and the investor could move in before Christmas. The house was created based on the standard project of the Kubis Lumio house, and thanks to the composition of the external and roof structures, it meets the parameters of a passive house.

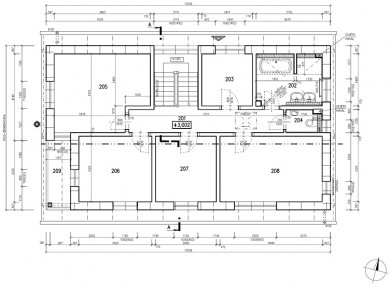

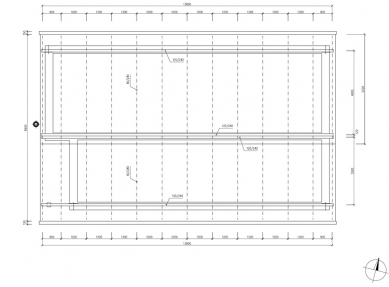

Even in its standard design, the Kubis Lumio house from RD Rýmařov combines modern architecture with contemporary requirements for functional interior solutions. The attic is not reduced by the sloping roof, so it has equally usable living space as the ground floor; the two sloping roofs opposite each other allow for non-standard lighting of the staircase through the skylight. Thanks to the modern architectural design, the investor can obtain a large apartment in a small house.

When added to this are other attributes of houses from Rýmařov - construction speed, a guaranteed and accessible price, a 30-year warranty on the structural system, which is also already low-energy in standard, characterized by high sound insulation, variability, and the possibility of realizing individual ideas - a house is created that attracts everyone who supports current trends in individual housing. Such is the investor - Mr. Otakar Jiránek, the director of Country Life (an operator of dining facilities with vegetarian snacks and stores focused on eco-agriculture products), whose corporate seat, also known as "The Ark in Nenačovice," was the very first house in passive standard built in the Czech Republic.

And it is in the new house built based on the standard project of Kubis Lumio that Mr. Jiránek will live starting this Christmas. His family house will, like his company’s headquarters, again be an act of a pioneer - it will be a passive family house built based on a standard project house. This is very significant, especially currently, when there is a lot of discussion and writing about passive houses, yet due to their small number, there are many myths and half-truths associated with them, similar to many years ago with timber constructions. And RD Rýmařov, as the largest timber construction manufacturer in our country, again confirms its position as a leader and shows that passive houses can be realized with standard projects, without exaggerated budget demands, and they are accessible to anyone who wants to live in a maximally energy-efficient manner.

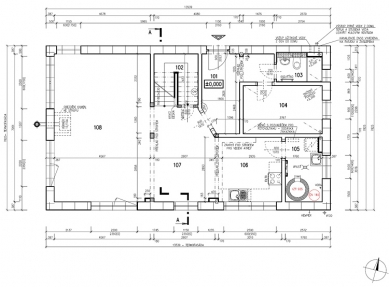

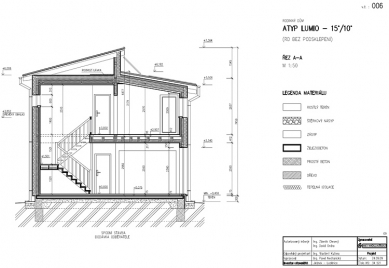

What differentiates this passive house from a regular Kubis Lumio house? At first glance, the changes in size and internal layout, reflecting the individual needs of the investor, are visible - the floor plan of the house is 13.5 x 8 meters, and compared to the standard project, the house has grown in both length and width. Thanks to the increase in the built-up area, the total usable area of the house has also increased, which represents an area of 83.5 m² in both above-ground floors (the house is not basement) for a total of 167 m².

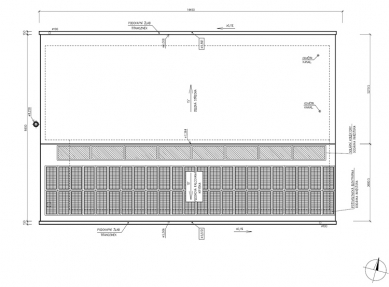

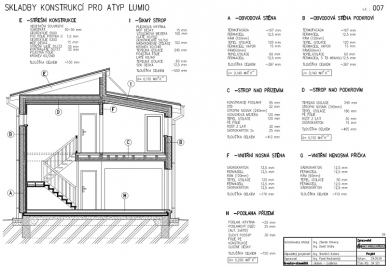

Less visible, but very significant for achieving the parameters of a passive house are the compositions of the constructions. While the standard house has, for example, an external wall thickness of 265 mm and a heat transfer coefficient U = 0.18 W/m²K, the atypical house has a thickness of 387 mm and a heat transfer coefficient U = 0.14 W/m²K. The internal and external cladding of all walls is similarly made of FERMACELL fiber cement boards, but for the passive house, vapor-retardant FERMACELL VAPOR fiber cement boards are additionally used on the external walls, which are part of the diffusely open structure of the house. A significant innovation in the composition of the external wall is the installation of a mounting partition with thermal insulation made of wood fiber.

The external wall (U = 0.14 W/m²K) has the following composition:

|

Even in its standard design, the Kubis Lumio house from RD Rýmařov combines modern architecture with contemporary requirements for functional interior solutions. The attic is not reduced by the sloping roof, so it has equally usable living space as the ground floor; the two sloping roofs opposite each other allow for non-standard lighting of the staircase through the skylight. Thanks to the modern architectural design, the investor can obtain a large apartment in a small house.

When added to this are other attributes of houses from Rýmařov - construction speed, a guaranteed and accessible price, a 30-year warranty on the structural system, which is also already low-energy in standard, characterized by high sound insulation, variability, and the possibility of realizing individual ideas - a house is created that attracts everyone who supports current trends in individual housing. Such is the investor - Mr. Otakar Jiránek, the director of Country Life (an operator of dining facilities with vegetarian snacks and stores focused on eco-agriculture products), whose corporate seat, also known as "The Ark in Nenačovice," was the very first house in passive standard built in the Czech Republic.

And it is in the new house built based on the standard project of Kubis Lumio that Mr. Jiránek will live starting this Christmas. His family house will, like his company’s headquarters, again be an act of a pioneer - it will be a passive family house built based on a standard project house. This is very significant, especially currently, when there is a lot of discussion and writing about passive houses, yet due to their small number, there are many myths and half-truths associated with them, similar to many years ago with timber constructions. And RD Rýmařov, as the largest timber construction manufacturer in our country, again confirms its position as a leader and shows that passive houses can be realized with standard projects, without exaggerated budget demands, and they are accessible to anyone who wants to live in a maximally energy-efficient manner.

What differentiates this passive house from a regular Kubis Lumio house? At first glance, the changes in size and internal layout, reflecting the individual needs of the investor, are visible - the floor plan of the house is 13.5 x 8 meters, and compared to the standard project, the house has grown in both length and width. Thanks to the increase in the built-up area, the total usable area of the house has also increased, which represents an area of 83.5 m² in both above-ground floors (the house is not basement) for a total of 167 m².

Less visible, but very significant for achieving the parameters of a passive house are the compositions of the constructions. While the standard house has, for example, an external wall thickness of 265 mm and a heat transfer coefficient U = 0.18 W/m²K, the atypical house has a thickness of 387 mm and a heat transfer coefficient U = 0.14 W/m²K. The internal and external cladding of all walls is similarly made of FERMACELL fiber cement boards, but for the passive house, vapor-retardant FERMACELL VAPOR fiber cement boards are additionally used on the external walls, which are part of the diffusely open structure of the house. A significant innovation in the composition of the external wall is the installation of a mounting partition with thermal insulation made of wood fiber.

The external wall (U = 0.14 W/m²K) has the following composition:

- FERMACELL fiber cement board 12.5 mm

- mounting partition with thermal insulation made of wood fiber 60 mm

- vapor-retardant FERMACELL Vapor fiber cement board 15 mm

- load-bearing frame with thermal insulation made of wood fiber 120 mm

- FERMACELL fiber cement board 12.5 mm

- thermal insulation made of wood fiber 160 mm

- diffusely open facade system

- drywall board 15 mm

- ceiling battens with thermal insulation made of wood fiber 60 mm

- vapor barrier

- rafters 60 x 24 mm with thermal insulation made of wood fiber 240 mm

- above-rafter thermal insulation made of wood fiber 100 mm

- counter battens, ventilated gap

- roof battens

- OSB board

- roof covering with tizanzinc

The English translation is powered by AI tool. Switch to Czech to view the original text source.

Related articles

0

28.05.2010 | On Saturday, June 5th, in the village of Blešno near Hradec Králové, a house will be "publicly" built

0

14.07.2009 | Architect Pavel Horák used FERMACELL materials for the commercial building in Kunice

0

25.05.2009 | RD Rýmařov is building a residential park CUBBE in Brno

0

06.05.2009 | 6.5 kWh/m²! The "Green Offices" project in Givisiez, Switzerland, breaks all records in terms of energy consumption..