SSBS / Prototype W02

Author's report

Our studio (at that time H.R.A. - Hoffman Rajniš Architects) has been developing a special modular construction system for building houses since 2002. Its foundation consists of wooden structural elements connected, braced, and fastened using a series of special metal components. The system, which is currently undergoing patenting, has been named: "Special Scaffolding Building System" – SBSS (Special Scaffolding Building System); the variant using wood is labeled Wood (W).

The system is completely universal, economical, easy and relatively quick to assemble. It is possible to intervene in the completed building at any time, to change it, enlarge it, or reduce it. The elements of the system remain intact after disassembly.

The horizontal and vertical parts of the load-bearing structure consist of wooden plank elements measuring 35 x 105 (210) mm. These elements are used to assemble frames that constitute the load-bearing parts of floors, walls, and ceilings. The joints between the wooden parts consist of simple metal connectors that can be easily and quickly assembled, as well as disassembled. The construction of the load-bearing skeleton is carried out in a manner similar to assembling scaffolding. The SSBS system is complemented by metal components ensuring connection (switching), bracing, and adjustable foundations for the wooden frames. The connectors are designed so that an adjustable hanger can be attached to each of them, supporting for example the basic elements of the facade or fittings.

System properties

The SSBS (W) system allows for extraordinary flexibility both at the inception and during the existence of the building. As there is no need to lay foundations, it is possible to build almost anywhere and in any situation. In the case of temporary buildings, it is possible to avoid complicated and often impractical procedures in urban and construction regulations. Assembly is relatively simple, and the building can be assembled (after a brief instruction) even by a family. It can be assembled as easily as, for example, a piece of IKEA furniture. Wooden elements are light and relatively inexpensive. Nothing is cut, drilled, or sanded; only the joints are tightened. The economic parameters are very competitive compared to traditional technologies. Our rapidly changing lives thus receive construction that is equally changeable and dynamic.

Prototyp SSBS (W) 02

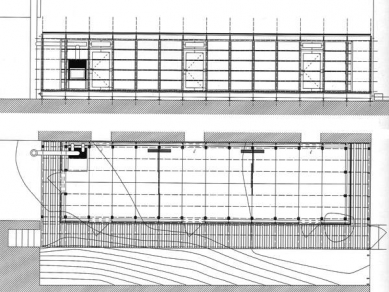

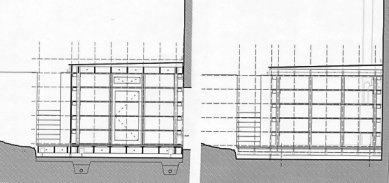

Residential studio in the garden. The goal of our clients (a family with three children) was to obtain a relatively dark ground floor for a flat, work, and relaxation area, illuminated by a space where the building intertwines with nature. A glass facade is attached to the wooden load-bearing system SSBS (W). The realization is shaded by the house and trees. The theme of the symbiosis of trees, plants, stones, glass, wooden grids with accents of metal joints represents the basic motif of this house. Certain hints of Zen architecture are not incidental. The building is partially seasonal. The parents have temporarily separated from the children using translucent partition walls. Each space has direct access to the garden.

On the shaded northern side of the residential building, we designed a residential studio that connects to a relatively narrow and specifically modified garden. With a rectangular floor plan, it adjoins the house and is connected to the ground floor rooms by a trio of glazed doors. The garden rises one level in the eastern direction, and its retaining walls form a small atrium in front of the side of the studio.

The use of the SSBS system brings numerous advantages

Very quick assembly.

The construction is based on a gravel bed without solid foundations on adjustable metal feet.

Both the horizontal and vertical frameworks consist of finished wooden parts (here spruce).

It can be disassembled in a very short time.

The studio has a fully glass facade, made up of double-glazed panels in frames of galvanized steel strip.

Bracing and connection of the structure consist of a system of steel cables with tensioners.

All joints are adjustable.

The floor components consist of a sandwich construction - ash industrial mosaic on OSB boards.

Our studio (at that time H.R.A. - Hoffman Rajniš Architects) has been developing a special modular construction system for building houses since 2002. Its foundation consists of wooden structural elements connected, braced, and fastened using a series of special metal components. The system, which is currently undergoing patenting, has been named: "Special Scaffolding Building System" – SBSS (Special Scaffolding Building System); the variant using wood is labeled Wood (W).

The system is completely universal, economical, easy and relatively quick to assemble. It is possible to intervene in the completed building at any time, to change it, enlarge it, or reduce it. The elements of the system remain intact after disassembly.

The horizontal and vertical parts of the load-bearing structure consist of wooden plank elements measuring 35 x 105 (210) mm. These elements are used to assemble frames that constitute the load-bearing parts of floors, walls, and ceilings. The joints between the wooden parts consist of simple metal connectors that can be easily and quickly assembled, as well as disassembled. The construction of the load-bearing skeleton is carried out in a manner similar to assembling scaffolding. The SSBS system is complemented by metal components ensuring connection (switching), bracing, and adjustable foundations for the wooden frames. The connectors are designed so that an adjustable hanger can be attached to each of them, supporting for example the basic elements of the facade or fittings.

System properties

The SSBS (W) system allows for extraordinary flexibility both at the inception and during the existence of the building. As there is no need to lay foundations, it is possible to build almost anywhere and in any situation. In the case of temporary buildings, it is possible to avoid complicated and often impractical procedures in urban and construction regulations. Assembly is relatively simple, and the building can be assembled (after a brief instruction) even by a family. It can be assembled as easily as, for example, a piece of IKEA furniture. Wooden elements are light and relatively inexpensive. Nothing is cut, drilled, or sanded; only the joints are tightened. The economic parameters are very competitive compared to traditional technologies. Our rapidly changing lives thus receive construction that is equally changeable and dynamic.

Prototyp SSBS (W) 02

Residential studio in the garden. The goal of our clients (a family with three children) was to obtain a relatively dark ground floor for a flat, work, and relaxation area, illuminated by a space where the building intertwines with nature. A glass facade is attached to the wooden load-bearing system SSBS (W). The realization is shaded by the house and trees. The theme of the symbiosis of trees, plants, stones, glass, wooden grids with accents of metal joints represents the basic motif of this house. Certain hints of Zen architecture are not incidental. The building is partially seasonal. The parents have temporarily separated from the children using translucent partition walls. Each space has direct access to the garden.

On the shaded northern side of the residential building, we designed a residential studio that connects to a relatively narrow and specifically modified garden. With a rectangular floor plan, it adjoins the house and is connected to the ground floor rooms by a trio of glazed doors. The garden rises one level in the eastern direction, and its retaining walls form a small atrium in front of the side of the studio.

The use of the SSBS system brings numerous advantages

Very quick assembly.

The construction is based on a gravel bed without solid foundations on adjustable metal feet.

Both the horizontal and vertical frameworks consist of finished wooden parts (here spruce).

It can be disassembled in a very short time.

The studio has a fully glass facade, made up of double-glazed panels in frames of galvanized steel strip.

Bracing and connection of the structure consist of a system of steel cables with tensioners.

All joints are adjustable.

The floor components consist of a sandwich construction - ash industrial mosaic on OSB boards.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

3 comments

add comment

Subject

Author

Date

kde lze sehnat montážní prvky

bohacek

25.07.06 06:54

Martin Rajniš říká:

Petr Šmídek

25.07.06 09:23

Jaké další pláště jsou možné?

Ondřej Prokop Vaněček

06.09.06 02:20

show all comments