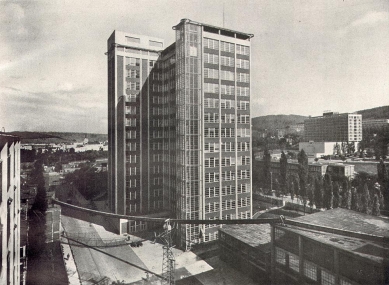

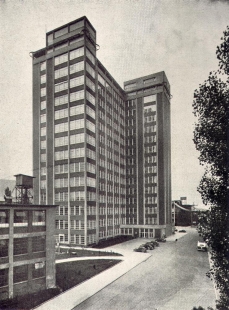

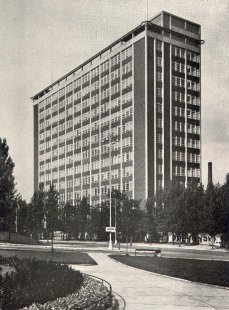

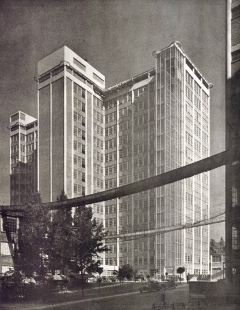

Administrative building of Baťa's factories

In 1894, Tomáš Baťa, a native of Zlín, founded a shoemaking workshop with his siblings Antonín and Anna Baťa. Through tireless diligence and entrepreneurial genius, he developed this workshop into the largest shoe factory in the world.

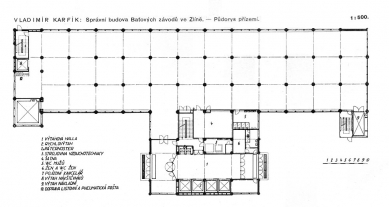

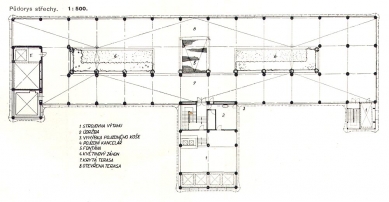

Zlín reached its final form in the stage of its development, caused by the unprecedented growth of Baťa's factories. The new administration building emphasizes that Zlín is the headquarters of a global enterprise, while the parent company establishes new satellite settlements in Bohemia and Moravia, through which increased production will be decentralized, continually expanding into new industries. - The systematic capturing of urban development within certain limits has already been positively confirmed and clearly outlined in the teachings of urban construction, but circumstances have always been stronger than theory. - Baťa's factories, however, always managed to derive from pure truths earlier than they became generalized. The new function of Zlín leads again to the recognition of another truth, that there is yet another element, and that is the highest goal of the spirit: art and its expression of monumentality, to which Zlín - a city of calculations and social and cultural institutions - had not yet established the necessary relationship. The concentration of administration prompted the first monumental construction: the central building of the factories. Baťa's factories strive for what they still needed, for architecture to provide them with a shield and a crown representing the pride of the enterprise: certainty and its stability. This follows years of seeking and rapid growth. Not only work and bread, but also art must come to the fore as a testament to a higher life alongside daily concerns. Art should create a framework for the work environment - this is the creed of J. A. Baťa - the successor. Tomáš Baťa - the founder had his love for Zlín not only from romanticism for his birthplace but also for its environment, where Moravian nature begins to provide its rich landscape beauty. He therefore sensed responsibly and nobly the need to create a human work, when in 1908 he summoned architect Jan Kotěra to build his Zlín home. This was an acknowledgment of the importance of the architect's function, created by his own instinct, and from there began the now-traditional division of labor between the builder and the constructor, which imprints Zlín with its unique character. Kotěra was succeeded by his student, architect F. L. Gahura, alongside whom came ing. architect Vladimír Karfík, who was entrusted with the responsible design of the administration building, to realize many of his American insights therein. - In its nature, however, this new tall building of Zlín differs from its American counterparts, which arose mainly due to a lack of space and the necessity of costly land. In Zlín, it was only the cost-effectiveness of operation and a constant consideration for the nature of the city in gardens that must never be violated.

The growing administrative agenda of Baťa's factories presented the company's leaders with a problem: to acquire additional buildings for administrative purposes or to concentrate all components in one place, vertically. After careful consideration of various advantages and disadvantages, a multi-story building was decided upon. The main advantage noted was: closer contact of all departments, reduction of time losses during transitions, which may only take minutes but reach significant numbers and values with a workforce of a thousand. Other advantages included: savings in building space, the possibility of using various mechanical devices, etc. The negative aspect was mainly considered regarding the necessity for a large number of expensive elevators and increased construction costs for reinforced foundations and a reinforced concrete frame. However, this last component burdens the overall budget less than might be expected.

General data.

From the floor of the first floor to the roof of the air conditioning extension on the 17th floor, the building has a height of 77.50 m. The constructive height of the floor is relatively high at 4.50 m due to the use of large halls. (…)

Heating and air conditioning.

All options were discussed, from radiator heating to radiant and electric heating. Finally, however, air conditioning was chosen, as the large number of employees in the spacious work halls requires - in addition to maintaining optimal temperature - also perfect air quality and cleanliness, lest productivity decline. The system is discussed in an article by M. John.

Water installations.

Hot water preparation is centralized, as is cooled drinking water for the drinking fountains placed on each floor. Since the water supply pressure is insufficient, water is pumped into reservoirs located on the 17th floor. Men's toilets are on every floor, women's toilets only on the second and ninth floors. The toilets have fixed, non-opening windows and are maintained with a double battery of exhaustors under a constant negative pressure; this prevents possible air flow from the toilet into the rest of the building and thereby the spread of odors. Hydrants are located in cabinets on a special riser, with a pump appropriately dimensioned. An automatic pump switch is placed in each cabinet. Rainwater is directed to the center of the building and drains through Mannesmann pipes in the core of the columns.

Electrical installation.

The building is richly equipped from this perspective, and possible later combinations and modifications were anticipated by laying down reserve pipes. Risers are concentrated in a continuous shaft near the main staircase. This shaft is accessible for repairs and adaptations across its entire height. In the sill walls, there is distribution for lighting, motor, telephone, and radio, with outlets spaced 3 meters apart. Loudspeakers are smoothly embedded into the wall face, spaced 6 meters apart. Intelligibility is very good, and the system is used for announcements concerning all employees; it can also be used for calling individuals. Ceiling lights can be turned off individually or in groups of six. Ample, waterproof outlets have been provided for both lighting and telephones in the case of freestanding desks.

Construction details.

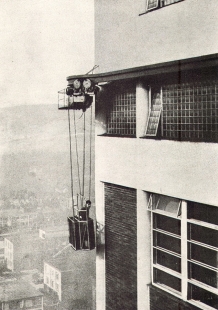

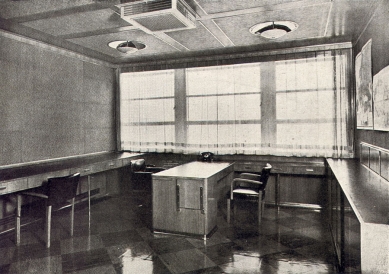

The outer walls are built of ordinary and hollow bricks, and covered in the façade with Slavíková tiles measuring 6.5x30 cm. Concrete surfaces are plastered with scraped plaster. The floors are concrete without sub-base. A leveling thin concrete, about 3 cm thick, was spread over the surface and covered with a cement topping, onto which a rubber floor was glued, first 2 mm thick raw rubber, which adheres very well to the cement surface. Then a standard rubber carpet, 4 mm thick, was glued, laid in squares averaging 1 m². Color tones and harmonies were chosen differently for each floor. This flooring has proven perfect in terms of acoustics as well as maintenance. For representative rooms, porous spongy rubber was used instead of the raw rubber layer. Here walking is as soft and springy as on a textile carpet. In the elevator hall and staircase, multicolored terrazzo divided by brass strips was used. The windows are double with blinds placed between the panes. Initially, combined windows were considered, but these require the blinds to be placed either in front of the windows or, better, behind the windows in the façade. However, this case is costly and the first case hinders air cooling in summer. The outer windows are fixed, non-opening, with just a narrow ventilation at the top and bottom (see detail). Ventilation is only used when air conditioning is not in operation. This method required washing the windows from the façade, using a mobile lift suspended on a trolley track on the main cornice.

Partitioning dividers.

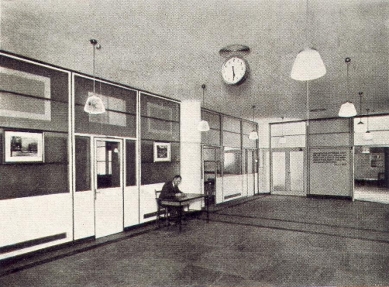

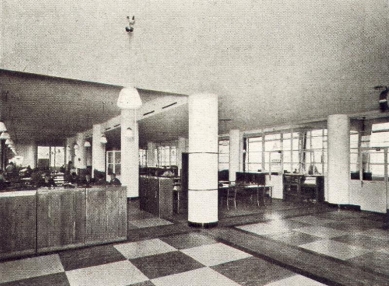

These partitions have been standardized for a constant distance between columns and ceiling height. To achieve as much lightness and delicacy in the profile as possible, a combination of wood and iron was chosen. They are constructed in several standard sections; besides solid and glazed panels, there are sections with single, double doors, with pass-through windows, etc. Installation and dismantling is very quick and simple. After unscrewing the rubber base and iron cover strips, the expansion screws are released; there is no screwing or fastening into floors, columns, and walls. Sections are equipped at the bottom with a grille for circulating air, secured against sight with a louvered profile and against sound transmission with a felt insert (see detail). The division of offices is mostly done by these partitions, so that load-bearing walls are only used in washrooms, elevators, etc. They allow for the greatest flexibility in spatial arrangement and adaptation to immediate operational needs.

Various devices.

In the building, there is a mail and package lift with automatic tilting, of the paternoster type. For the removal of debris and discarded paper, there is a shaft running through all floors, equipped with a safety lock. At the bottom, it ends in a collector, from which it directly drops into a cargo truck. For fire reporting, there are automatic electric alarms.

Project and construction execution.

The project was entrusted to ing. architect Vladimír Karfík, while the chief builder during the entire construction was builder Arnošt Sehnal, static calculations and the design of the reinforced concrete frame were carried out by ing. Alfons Hübner, the air conditioning project was developed with the inclusion of consultants by Maxmilian John, the water installation project by Jan Vojta, and the electrical installation project by Josef Zavřel.

Air conditioning of the elevator office.

A challenging problem was satisfactorily solving the air conditioning of the elevator office. The elevator shaft is located on the outside of the building, and three of its sides are made up of windows. Therefore, the cabin is exposed to significant cooling in winter and direct sunlight in summer. At the same time, the temperature inside the shaft is unevenly distributed due to the significant height. We therefore divided the heating into two parts: a stable, steam, partial heating of the shaft using hot air equipment at the bottom of the shaft, and a movable, electrically heated air conditioning device located directly on the cabin. Automatic temperature control here is electrical and also has two circuits. The first circuit consists of an electric temperature regulator, placed in the cabin on the outside of the floor, and an automatic valve on the hot air device, connected by a 40 m long loose cable. With this device, the surrounding temperature of the cabin is maintained at 15° regardless of the height at which the cabin is located. The second circuit maintains a constant temperature inside the cabin. The electric temperature regulator, adjustable to any temperature in the range of 18-25°, is mounted on the wall of the cabin and controls both the electrical heaters and the cooling machine of the air conditioning device. The unit is located on the ceiling of the cabin.

Mobile lift for window cleaning.

Washing windows of factory buildings in Zlín has always been a problem. The windows are fixed, only equipped with smaller, ventilation wings. Washing from an external ladder is difficult at greater heights. A radical solution was therefore chosen for the administration building. Windows are washed from the outside using a mobile lift suspended on a trolley track on the main cornice of the building, elevated 67 m above the sidewalk. This made it possible to utilize windows most suitable for an air-conditioned building, i.e., largely fixed and non-opening. Only narrow ventilation openings open when the device is not in operation. The lift basket is designed for 2 persons or 1 person and a container with water and cleaning agents or paints for touch-up jobs. The cleaner has four buttons on the basket for directions: down, up, forward, and backward. If a combination of 2 buttons is pressed, the basket moves diagonally in the resultant direction. The supply cable to the lift freely coils into a special basket when the lift rises; an automatic reel was dismissed, as a coiled cable in cold weather could freeze and hinder unwinding. The trolley track that goes around the entire building could not be sharply bent around the corners; it had to be curved with considerable radius curves, which have become characteristic of the entire silhouette of the building. The trolley track has a switch at one point, where the cleaner enters into a room for cleaners, situated on the 15th floor. Here the cleaner can safely prepare cleaning supplies, fill water, maintain the machine, and, if necessary, repair it. The room houses paint for small touch-ups and reserve tubes, by which the façade is illuminated under normal conditions. The problem of swing of the basket, which is significant especially in the lower floors when the suspension cables are long, was very successfully addressed. This swing would greatly complicate washing, as if pressed against the glass, the lift would immediately move away from the façade. Therefore, two electromagnets are suspended from the basket on short chains, allowing the cleaner to attach to any part of the iron windows. The switches for controlling the electromagnets are located directly on the magnets. Furthermore, there is a safeguard to prevent the cleaner from accidentally setting the entire basket in motion if they forget to disconnect both electromagnets. The arrangement has proven very effective; it requires only one attendant to care for the cleaning of the entire façade. However, it is constantly in operation, considering that the window area exceeds 15,000 m² and that cleaning is not possible in bad weather. The main advantage, besides the speed of washing, is that the whole operation is completely safe.

Zlín reached its final form in the stage of its development, caused by the unprecedented growth of Baťa's factories. The new administration building emphasizes that Zlín is the headquarters of a global enterprise, while the parent company establishes new satellite settlements in Bohemia and Moravia, through which increased production will be decentralized, continually expanding into new industries. - The systematic capturing of urban development within certain limits has already been positively confirmed and clearly outlined in the teachings of urban construction, but circumstances have always been stronger than theory. - Baťa's factories, however, always managed to derive from pure truths earlier than they became generalized. The new function of Zlín leads again to the recognition of another truth, that there is yet another element, and that is the highest goal of the spirit: art and its expression of monumentality, to which Zlín - a city of calculations and social and cultural institutions - had not yet established the necessary relationship. The concentration of administration prompted the first monumental construction: the central building of the factories. Baťa's factories strive for what they still needed, for architecture to provide them with a shield and a crown representing the pride of the enterprise: certainty and its stability. This follows years of seeking and rapid growth. Not only work and bread, but also art must come to the fore as a testament to a higher life alongside daily concerns. Art should create a framework for the work environment - this is the creed of J. A. Baťa - the successor. Tomáš Baťa - the founder had his love for Zlín not only from romanticism for his birthplace but also for its environment, where Moravian nature begins to provide its rich landscape beauty. He therefore sensed responsibly and nobly the need to create a human work, when in 1908 he summoned architect Jan Kotěra to build his Zlín home. This was an acknowledgment of the importance of the architect's function, created by his own instinct, and from there began the now-traditional division of labor between the builder and the constructor, which imprints Zlín with its unique character. Kotěra was succeeded by his student, architect F. L. Gahura, alongside whom came ing. architect Vladimír Karfík, who was entrusted with the responsible design of the administration building, to realize many of his American insights therein. - In its nature, however, this new tall building of Zlín differs from its American counterparts, which arose mainly due to a lack of space and the necessity of costly land. In Zlín, it was only the cost-effectiveness of operation and a constant consideration for the nature of the city in gardens that must never be violated.

The growing administrative agenda of Baťa's factories presented the company's leaders with a problem: to acquire additional buildings for administrative purposes or to concentrate all components in one place, vertically. After careful consideration of various advantages and disadvantages, a multi-story building was decided upon. The main advantage noted was: closer contact of all departments, reduction of time losses during transitions, which may only take minutes but reach significant numbers and values with a workforce of a thousand. Other advantages included: savings in building space, the possibility of using various mechanical devices, etc. The negative aspect was mainly considered regarding the necessity for a large number of expensive elevators and increased construction costs for reinforced foundations and a reinforced concrete frame. However, this last component burdens the overall budget less than might be expected.

General data.

From the floor of the first floor to the roof of the air conditioning extension on the 17th floor, the building has a height of 77.50 m. The constructive height of the floor is relatively high at 4.50 m due to the use of large halls. (…)

Heating and air conditioning.

All options were discussed, from radiator heating to radiant and electric heating. Finally, however, air conditioning was chosen, as the large number of employees in the spacious work halls requires - in addition to maintaining optimal temperature - also perfect air quality and cleanliness, lest productivity decline. The system is discussed in an article by M. John.

Water installations.

Hot water preparation is centralized, as is cooled drinking water for the drinking fountains placed on each floor. Since the water supply pressure is insufficient, water is pumped into reservoirs located on the 17th floor. Men's toilets are on every floor, women's toilets only on the second and ninth floors. The toilets have fixed, non-opening windows and are maintained with a double battery of exhaustors under a constant negative pressure; this prevents possible air flow from the toilet into the rest of the building and thereby the spread of odors. Hydrants are located in cabinets on a special riser, with a pump appropriately dimensioned. An automatic pump switch is placed in each cabinet. Rainwater is directed to the center of the building and drains through Mannesmann pipes in the core of the columns.

Electrical installation.

The building is richly equipped from this perspective, and possible later combinations and modifications were anticipated by laying down reserve pipes. Risers are concentrated in a continuous shaft near the main staircase. This shaft is accessible for repairs and adaptations across its entire height. In the sill walls, there is distribution for lighting, motor, telephone, and radio, with outlets spaced 3 meters apart. Loudspeakers are smoothly embedded into the wall face, spaced 6 meters apart. Intelligibility is very good, and the system is used for announcements concerning all employees; it can also be used for calling individuals. Ceiling lights can be turned off individually or in groups of six. Ample, waterproof outlets have been provided for both lighting and telephones in the case of freestanding desks.

Construction details.

The outer walls are built of ordinary and hollow bricks, and covered in the façade with Slavíková tiles measuring 6.5x30 cm. Concrete surfaces are plastered with scraped plaster. The floors are concrete without sub-base. A leveling thin concrete, about 3 cm thick, was spread over the surface and covered with a cement topping, onto which a rubber floor was glued, first 2 mm thick raw rubber, which adheres very well to the cement surface. Then a standard rubber carpet, 4 mm thick, was glued, laid in squares averaging 1 m². Color tones and harmonies were chosen differently for each floor. This flooring has proven perfect in terms of acoustics as well as maintenance. For representative rooms, porous spongy rubber was used instead of the raw rubber layer. Here walking is as soft and springy as on a textile carpet. In the elevator hall and staircase, multicolored terrazzo divided by brass strips was used. The windows are double with blinds placed between the panes. Initially, combined windows were considered, but these require the blinds to be placed either in front of the windows or, better, behind the windows in the façade. However, this case is costly and the first case hinders air cooling in summer. The outer windows are fixed, non-opening, with just a narrow ventilation at the top and bottom (see detail). Ventilation is only used when air conditioning is not in operation. This method required washing the windows from the façade, using a mobile lift suspended on a trolley track on the main cornice.

Partitioning dividers.

These partitions have been standardized for a constant distance between columns and ceiling height. To achieve as much lightness and delicacy in the profile as possible, a combination of wood and iron was chosen. They are constructed in several standard sections; besides solid and glazed panels, there are sections with single, double doors, with pass-through windows, etc. Installation and dismantling is very quick and simple. After unscrewing the rubber base and iron cover strips, the expansion screws are released; there is no screwing or fastening into floors, columns, and walls. Sections are equipped at the bottom with a grille for circulating air, secured against sight with a louvered profile and against sound transmission with a felt insert (see detail). The division of offices is mostly done by these partitions, so that load-bearing walls are only used in washrooms, elevators, etc. They allow for the greatest flexibility in spatial arrangement and adaptation to immediate operational needs.

Various devices.

In the building, there is a mail and package lift with automatic tilting, of the paternoster type. For the removal of debris and discarded paper, there is a shaft running through all floors, equipped with a safety lock. At the bottom, it ends in a collector, from which it directly drops into a cargo truck. For fire reporting, there are automatic electric alarms.

Project and construction execution.

The project was entrusted to ing. architect Vladimír Karfík, while the chief builder during the entire construction was builder Arnošt Sehnal, static calculations and the design of the reinforced concrete frame were carried out by ing. Alfons Hübner, the air conditioning project was developed with the inclusion of consultants by Maxmilian John, the water installation project by Jan Vojta, and the electrical installation project by Josef Zavřel.

Air conditioning of the elevator office.

A challenging problem was satisfactorily solving the air conditioning of the elevator office. The elevator shaft is located on the outside of the building, and three of its sides are made up of windows. Therefore, the cabin is exposed to significant cooling in winter and direct sunlight in summer. At the same time, the temperature inside the shaft is unevenly distributed due to the significant height. We therefore divided the heating into two parts: a stable, steam, partial heating of the shaft using hot air equipment at the bottom of the shaft, and a movable, electrically heated air conditioning device located directly on the cabin. Automatic temperature control here is electrical and also has two circuits. The first circuit consists of an electric temperature regulator, placed in the cabin on the outside of the floor, and an automatic valve on the hot air device, connected by a 40 m long loose cable. With this device, the surrounding temperature of the cabin is maintained at 15° regardless of the height at which the cabin is located. The second circuit maintains a constant temperature inside the cabin. The electric temperature regulator, adjustable to any temperature in the range of 18-25°, is mounted on the wall of the cabin and controls both the electrical heaters and the cooling machine of the air conditioning device. The unit is located on the ceiling of the cabin.

Mobile lift for window cleaning.

Washing windows of factory buildings in Zlín has always been a problem. The windows are fixed, only equipped with smaller, ventilation wings. Washing from an external ladder is difficult at greater heights. A radical solution was therefore chosen for the administration building. Windows are washed from the outside using a mobile lift suspended on a trolley track on the main cornice of the building, elevated 67 m above the sidewalk. This made it possible to utilize windows most suitable for an air-conditioned building, i.e., largely fixed and non-opening. Only narrow ventilation openings open when the device is not in operation. The lift basket is designed for 2 persons or 1 person and a container with water and cleaning agents or paints for touch-up jobs. The cleaner has four buttons on the basket for directions: down, up, forward, and backward. If a combination of 2 buttons is pressed, the basket moves diagonally in the resultant direction. The supply cable to the lift freely coils into a special basket when the lift rises; an automatic reel was dismissed, as a coiled cable in cold weather could freeze and hinder unwinding. The trolley track that goes around the entire building could not be sharply bent around the corners; it had to be curved with considerable radius curves, which have become characteristic of the entire silhouette of the building. The trolley track has a switch at one point, where the cleaner enters into a room for cleaners, situated on the 15th floor. Here the cleaner can safely prepare cleaning supplies, fill water, maintain the machine, and, if necessary, repair it. The room houses paint for small touch-ups and reserve tubes, by which the façade is illuminated under normal conditions. The problem of swing of the basket, which is significant especially in the lower floors when the suspension cables are long, was very successfully addressed. This swing would greatly complicate washing, as if pressed against the glass, the lift would immediately move away from the façade. Therefore, two electromagnets are suspended from the basket on short chains, allowing the cleaner to attach to any part of the iron windows. The switches for controlling the electromagnets are located directly on the magnets. Furthermore, there is a safeguard to prevent the cleaner from accidentally setting the entire basket in motion if they forget to disconnect both electromagnets. The arrangement has proven very effective; it requires only one attendant to care for the cleaning of the entire façade. However, it is constantly in operation, considering that the window area exceeds 15,000 m² and that cleaning is not possible in bad weather. The main advantage, besides the speed of washing, is that the whole operation is completely safe.

Vladimír Karfík, Alois Kubiček

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment