Expansion of the Hunsett Mill

Hunsett Mill

The Norfolk Broads are an artificial landscape of outstanding natural beauty, a man-made wetland sustained through human intervention of water pumping mills, dykes, and canals. After hundreds of years of industrial use of the natural landscape, the recent decades have seen increasing emphasis on conservation and a managed retreat back to nature. The Hunsett Mill project was founded on similar principles, whereby careless piecemeal development, harmful to the immediate context and in conflict with local flood ecology was removed and replaced with an intervention that is contemporary in expression but deeply embedded in the local context. It is all but self-sufficient in energy, water, and waste, with an actively positive effect on local ecology. The design considered its embodied energy and method of construction as well as its efficiency during occupation. The environmental aims are directly embodied in the architectural concept to achieve a building that appears robust, pure, and simple, with a clarity of space and consistency across scales and materialities.

PROJECT BACKGROUND

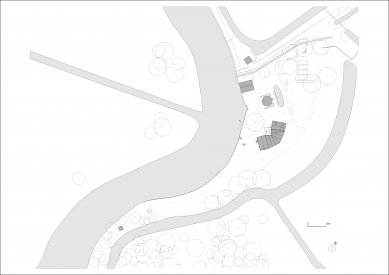

Hunsett Mill is a remote water pumping mill located in the historic Norfolk Broads National Park, situated beside the River Ant, upstream from the Sutton Broads. The house was a residence for the Keeper of the Mill until 1900, when the advent of electricity rendered wind-powered pumps obsolete. Since the end of its working life, the house has been used as a private residence, but has remained an important piece of local heritage, standing adjacent to the well-known historic grade 2 listed Hunsett Mill.

Building History

Throughout its life in the 20th century, the house suffered from a series of ill-conceived extensions, added to alleviate the original house’s spatial shortcomings. All of these extensions negatively affected the setting of the original house and caused subsidence and repeated flooding.

When the owners of the house needed further space, it was decided not to add yet another incremental extension, but to reinstate the tiny 19th-century Mill Keeper’s house to its original proportions, with only a single new extension added to one side.

The new extension

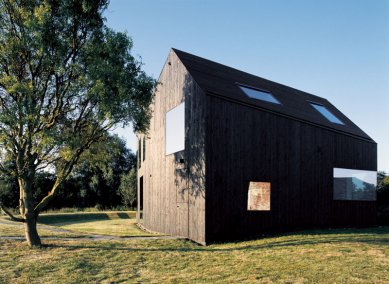

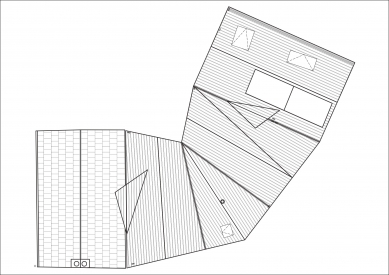

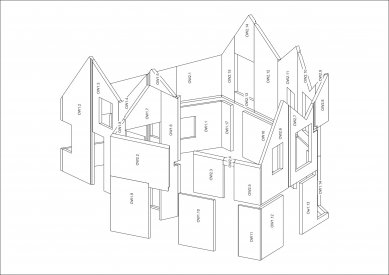

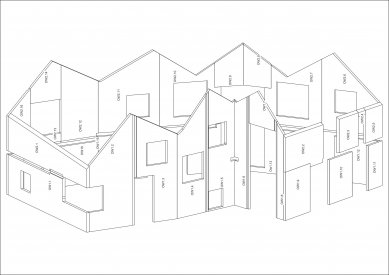

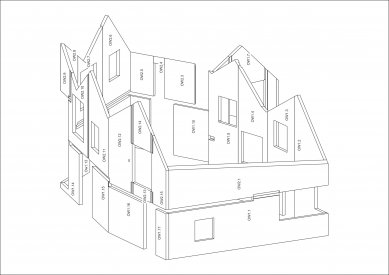

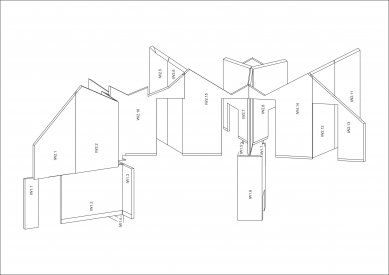

In order for the new extension to retreat behind the listed setting of the mill, the new addition is conceived as a shadow of the existing house. By adding a dark volume to the existing brick volume and by virtue of the chosen facade geometry, the exact shape of the extension volume seems ambiguous from afar. When inspected at a closer distance, the radically modern approach is mediated by the image of pitched roofs and dark timber boards that are a historic part of the Broads vernacular language. The massing and proportions of the new addition are configured to remain subordinate to the original building, yet the charred timber cladding helps it to settle into its context. The intervention appears as if it always belonged to the site, without reverting to false mimicry of the vernacular. The extension is made entirely from solid laminated wood, exposed as interior finish and clad in charred cedar boards externally. Ground source heat pumps, passive solar heating, and independent water well supply make the house almost fully self-sufficient.

DESIGN

The new extension

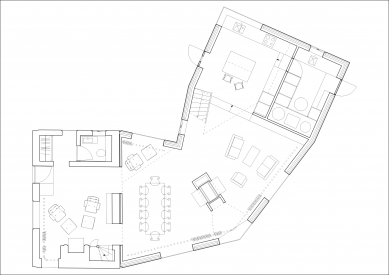

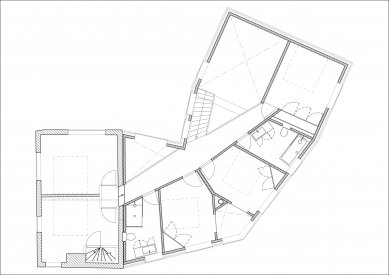

The house had been extended 5 times in the 20th century, with each extension adding on specific new rooms like kitchen, bathroom, and bedroom, but the resulting agglomeration of extensions was aesthetically and functionally of very low quality. The client requested an enlargement of the house to create more open living spaces and two additional bedrooms. Rather than adding on any more extensions, the design team decided to demolish all previous extensions and to return the cottage to its original shape, with only one new extension added in the back. Planning restrictions allowed only very slight increase in floorspace over the previous dwelling and imposed tight restrictions on roof heights, limiting any extensions to the ridge heights of the existing cottage. The extension overcomes these limitations of size and height by creating a very open ground floor layout with three small, double-height spaces that create an impression of spatial generosity and allow for the placement of large windows looking out towards the Mill and over the marshes. The open ground floor is structured by a fireplace and changes in floor level to create distinct kitchen, dining, and living areas (3). The first floor contains all of the 5 bedrooms as well as two bathrooms, interspersed with the voids created by the double-height spaces. While some of the bedrooms are only 7 square meters in size, they use the space under the roof pitches, full height mirrors on some walls, large external windows as well as internal windows into the void and towards the ground floor living rooms to create a feeling of capaciousness.

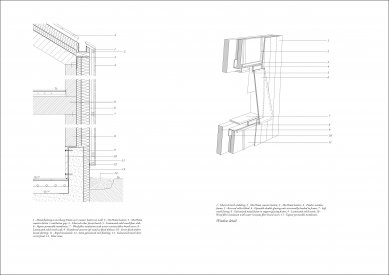

All internal walls and ceilings consist of the exposed timber structure. The exposure of the structure captures the essence of the geometry and materiality of the interior. The purity of the finish is assured by careful detailing and concealment of servicing. Where doors were required in timber walls, they were built to match the thickness and finish to create a continuity of material feel and appearance. Space is optimized by integrating fittings, wardrobes, and the fireplace into the timber walls. Limestone tiling for the bathrooms is color matched to the exposed timber so that there is little visual distinction between them and the rest of the house.

The main staircase is designed as light and unobtrusive as possible. It was manufactured from 4mm steel plates which are sunk into a slotted recess in the solid timber wall. The majority of floors are finished with limed, dark baked oak planks to complement the golden hue of the larch timber walls. In order for the staircase threads to become continuous with the floor, 3mm baked oak strips were directly bonded to the mild steel and limed in place.

Much like the original cottage, openings are arranged to first respond to the internal configuration. Every room is flooded with natural daylight and blessed with framed views of the windmill and surrounding landscape. Glazing in the kitchen rests on the worktops and permits views to the garden. Fixed panes of glass form a continuous surface with the cladding, to integrate with the geometry of the exterior and assure the airtightness of the interior, which relies instead on regulated stack effect ventilation through openings in the roof.

ECOLOGICAL LANDSCAPING

Flood defense

The marshes behind Hunsett Mill are considered an environmentally sensitive area and part of the Broads National Park. Though attempts have been made to cultivate the land in the past, it was decided that the land should be returned to its natural marshland state, under a ‘Higher Level Stewardship’ agreement with Natural England. The resulting higher water levels would have increased the risk of flooding the Hunsett Mill and the cottage, compelling the owners of the site to construct a series of flooding countermeasures as an integral part of the project. The mill, cottage, and low-lying marshes were previously protected from flooding by an embankment running parallel to the river, starting from Sutton Broad and running some 5km upstream to Wayford Bridge. In recent years the condition of the flood bank has progressively worsened, resulting in instances of flooding at Hunsett Mill and the adjacent fields and forests.

Given the difficulty in access, and poor ground and material conditions it was decided that the most sustainable scheme would be to abandon the existing line of defense downstream of Hunsett Mill and to construct a new bank immediately behind the buildings. The new flood bank is a small, secure, and easily maintainable defense while at the same time allowing the abandonment of subsequent downstream defenses, thereby returning 25 hectares of forest and grassland around Hunsett Mill to its pre-industrial marshland condition.

This land will form an extension to the adjacent Sutton Fen Nature Reserve of the RSPB, adding to the existing tranquil oasis of wetland wilderness, full of rare and endangered wildlife in the midst of the hustle.

The garden

The landscaping strategy for the garden is based on the use of local species in order to blend with the local ecosystem, yet to create a controlled appearance and frame the architecture. A wide selection of species has been used to design flowerbeds around the house and along the river. The color and spread size of each plant has been arranged according to the use of the garden: tall plants have created privacy while short bushes have framed views of the Mill from the river. Different color schemes have created spaces with different identities within the garden. The perennials will change their appearance with the seasons; hence the garden will blend in with the surrounding landscape at any time of the year. Using a large variety of indigenous plants had the effect of boosting the biodiversity of the site.

SUSTAINABLE MATERIALS

Embodied energy

With a desire for the new intervention to be as ecologically responsible as possible, emphasis was placed on the carbon cost of construction and the overall embodied energy expenditure at the time of construction. Materials throughout are sustainable, simple, and natural. The use of materials has been reduced to an absolute minimum by engineering out superfluous material. The structure is entirely made from solid cross-laminated timber walls, slabs, and roofs. This material possesses manifold advantages. As well as acting as the primary structural element, the material functions as an effective insulating member, and also as thermal mass to regulate the internal temperature of the dwelling, reducing the need for nighttime heating. No internal cladding has been used as all timber is left exposed. The timber is FSC certified, meaning it is harvested from sustainable forests where more trees are planted than felled, the welfare of those producing the material is assured, and the reasonable maximum travel distances for the transport of materials are enforced. This verifiable life-cycle approach to the material assures that the house functions as a carbon sink, where the carbon content of the wood is counted against any other carbon cost in the build, and is only returned to the atmosphere when the material is burned as biomass fuel at the end of its life.

Structurally, the stiff “folded plate” of the roof was used in conjunction with the first-floor internal timber panel partitions to suspend the first-floor timber floor plate from the roof, increasing the amount of open space on the ground. A lightweight factory-produced structural solution reduced heavy plant requirement on site, allowing the foundations to be reduced to small diameter driven piles with virtually no piling mat requirements apart from leveling (16). The use of concrete was restricted to the ground bearing slab that sits in the floodplain. In this way, the extent to which the earth was broken was minimal, and no by-products were released into the ground or river, safeguarding the ecological balance of the immediate context, as per the requirements of EMP3.

The laminated timber core of the building is an inherently low-waste system. By designing and fabricating components off-site using a process of computer-driven specification and CNC milling, waste and abortive work was marginalized. This system also respects the welfare of the laborers working during the build. Levels of risk to the safety of personnel, the presence of plant noise and dust were much lower compared to builds using traditional techniques.

The building has high standards of insulation, airtightness, solar control glazing, and high thermal mass. To weatherproof the building in a low-maintenance rainscreen cladding, we adapted a centuries-old, but mostly forgotten, technique of timber preservation, known as superficial charring. In Hunsett Mill, cedar boards have been chosen for their superior longevity and charred to create a surface finish that is humane, tactile, and natural, free of chemical treatments and with a very modest maintenance requirement. The charred cladding creates a contrast in color with the brick construction of the mill cottage and contributes to define a clear distinction between the original and the extension. The rough texture of the charred boards contrasts with the crisp details of the mirrored frameless windows. The blackness also references the tradition of tarred utilitarian buildings one still finds in Norfolk today.

Yakisugi (Charred timber)

Charred timber in the Norfolk vernacular and today

Charring was traditionally used as a method for preserving timber used for boat quays and quay headings, where the timber was submerged in water and the charring sealed the wood. Charred timber is not widely used any longer and the craftsmanship of charring has faded away from knowledge.

Charred timber in Japanese vernacular and today

In Japan charring has a long tradition and has been used to preserve timber cladding and increase its longevity. The charring seals the surface of the timber and burns out a number of oils that usually attract insects, leaving behind a black-silver surface layer of carbon/coal that protects the board. In Japan’s construction industry, charring is a fairly common practice where specialized manufacturers produce charred timber in a semi-industrial way. This ensures the quality is high and consistent throughout the production process and results in an economic product.

Charred timber at Hunsett Mill

Attempts to source charred timber locally to clad the new extension failed for a number of reasons: The charring was carried out manually using a propane gas-powered blowtorch which created only light superficial charring whilst using energy in a wasteful way. Samples showed that the quality of the charring was poor and would have resulted in flaking of the char. For quality, environmental, but also economic reasons, it was therefore decided to use imported timber for the external rainscreen cladding. The charred boards were sourced in Japan, providing a product of a higher quality but still lower cost than possible to source in the UK. Japanese charred timber also proved to be more sustainable during its manufacture; its transport used shipment to the UK. Two types of charring have been used to clad the new extension. The roof cladding boards were first charred and subsequently sandblasted. The vertical cladding boards are charred silver only.

ENERGY

Low-Tech and High-Tech

Where possible, the building takes a decided ‘low-tech’ approach to its internal environment and servicing. Orientation, insulation and fabric, and the positioning of windows maximizes internal daylight. The heart of the house is a double height area, flooded with light, affording dramatic views of the wilderness outside. The fundamental design move was to ensure maximum daylight and solar exposure during the winter months to benefit from free solar passive heating. Conversely, passive stack ventilation and argon-filled ‘Pilkington SunCool’ solar control glass prevent summer overheating. By leaving the internal surfaces of the laminated timber as a finish, its thermal mass capacity is best utilized, to harness the heat from solar gain captured during the day for steady release in the evenings. To precipitate natural ventilation in warmer months, several double-height spaces with individually controlled outlets create stack effects, drawing in fresh air. These passive techniques, married with the use of self-sufficient heating and servicing facilities, create redundancies so that the internal environment of the new extension is always pleasant while consuming a small fraction of the energy of the spaces it replaced.

Self Sufficiency

Hunsett Mill operates almost independently; electricity is the only off-site resource connected to the property. Nonetheless, the use of energy-efficient and motion-activated fixtures assures that electrical consumption is very low relative to the size of the house. The occupant sources electricity from ‘Good Energy’, the only wholly renewable energy provider in the UK. Not only can this be considered better for the environment than on-site per-dwelling micro-generation in certain circumstances, it also helps support and promote such companies as a realistic alternative.

Passive design strategies reduce dependency on artificial heating for much of the year, yet during the winter months, a wood-fired stove is used as required as a carbon-neutral method of maintaining internal comfort.

Fuel is harvested from the garden and local woodland by the occupant. Hot water and central heating requirements are catered for in two ways. Firstly, the property employs a Viessmann ground source heat pump.

The site has a very shallow water table; as a result, the buried slinky pipes have excellent ground coupling connectivity and will enable the heat pump to operate at maximum efficiency. Underfloor heating is used throughout with zonal controls providing local temperature control and monitoring. While the heat pump installation is very simple to use, a reduced form operating guidance sheet is provided in the utility room. This compliments the full operating and maintenance manual provided to support all the systems. Secondly, domestic hot water provision is complemented by the inclusion of 2 square meters of high-performance vacuum tube solar thermal collectors to the roof, providing up to 60% of the domestic hot water requirement of the property. This equates to a 6% contribution in terms of overall renewable contributions.

Water management

Hunsett Mill operates in total independence with regards to water management. Fresh water is sourced from a dedicated domestic water borehole located within the garden, with the associated pumps and filtering located within the property’s riverside boathouse. The owner has minimized water usage by the use of efficient fittings – toilets are dual flush, domestic appliances are AAA-rated and water connections are ‘low flow’. In spite of these measures, the use of fresh water is further minimized by capturing rainwater on site, harvested via the nearby windmill pond. The water is used for irrigating the local planting and garden. Foul waste is treated on site via a low maintenance extended aeration treatment tank. This system processes effluent in a self-contained chamber designed to actively encourage bacterial breakdown of sewerage. The system operates purely on gravity and has no moving parts. The final discharge is into the adjacent watercourse with full EA and Broads Authority consent.

PROJECT BACKGROUND

Hunsett Mill is a remote water pumping mill located in the historic Norfolk Broads National Park, situated beside the River Ant, upstream from the Sutton Broads. The house was a residence for the Keeper of the Mill until 1900, when the advent of electricity rendered wind-powered pumps obsolete. Since the end of its working life, the house has been used as a private residence, but has remained an important piece of local heritage, standing adjacent to the well-known historic grade 2 listed Hunsett Mill.

Building History

Throughout its life in the 20th century, the house suffered from a series of ill-conceived extensions, added to alleviate the original house’s spatial shortcomings. All of these extensions negatively affected the setting of the original house and caused subsidence and repeated flooding.

When the owners of the house needed further space, it was decided not to add yet another incremental extension, but to reinstate the tiny 19th-century Mill Keeper’s house to its original proportions, with only a single new extension added to one side.

The new extension

In order for the new extension to retreat behind the listed setting of the mill, the new addition is conceived as a shadow of the existing house. By adding a dark volume to the existing brick volume and by virtue of the chosen facade geometry, the exact shape of the extension volume seems ambiguous from afar. When inspected at a closer distance, the radically modern approach is mediated by the image of pitched roofs and dark timber boards that are a historic part of the Broads vernacular language. The massing and proportions of the new addition are configured to remain subordinate to the original building, yet the charred timber cladding helps it to settle into its context. The intervention appears as if it always belonged to the site, without reverting to false mimicry of the vernacular. The extension is made entirely from solid laminated wood, exposed as interior finish and clad in charred cedar boards externally. Ground source heat pumps, passive solar heating, and independent water well supply make the house almost fully self-sufficient.

DESIGN

The new extension

The house had been extended 5 times in the 20th century, with each extension adding on specific new rooms like kitchen, bathroom, and bedroom, but the resulting agglomeration of extensions was aesthetically and functionally of very low quality. The client requested an enlargement of the house to create more open living spaces and two additional bedrooms. Rather than adding on any more extensions, the design team decided to demolish all previous extensions and to return the cottage to its original shape, with only one new extension added in the back. Planning restrictions allowed only very slight increase in floorspace over the previous dwelling and imposed tight restrictions on roof heights, limiting any extensions to the ridge heights of the existing cottage. The extension overcomes these limitations of size and height by creating a very open ground floor layout with three small, double-height spaces that create an impression of spatial generosity and allow for the placement of large windows looking out towards the Mill and over the marshes. The open ground floor is structured by a fireplace and changes in floor level to create distinct kitchen, dining, and living areas (3). The first floor contains all of the 5 bedrooms as well as two bathrooms, interspersed with the voids created by the double-height spaces. While some of the bedrooms are only 7 square meters in size, they use the space under the roof pitches, full height mirrors on some walls, large external windows as well as internal windows into the void and towards the ground floor living rooms to create a feeling of capaciousness.

All internal walls and ceilings consist of the exposed timber structure. The exposure of the structure captures the essence of the geometry and materiality of the interior. The purity of the finish is assured by careful detailing and concealment of servicing. Where doors were required in timber walls, they were built to match the thickness and finish to create a continuity of material feel and appearance. Space is optimized by integrating fittings, wardrobes, and the fireplace into the timber walls. Limestone tiling for the bathrooms is color matched to the exposed timber so that there is little visual distinction between them and the rest of the house.

The main staircase is designed as light and unobtrusive as possible. It was manufactured from 4mm steel plates which are sunk into a slotted recess in the solid timber wall. The majority of floors are finished with limed, dark baked oak planks to complement the golden hue of the larch timber walls. In order for the staircase threads to become continuous with the floor, 3mm baked oak strips were directly bonded to the mild steel and limed in place.

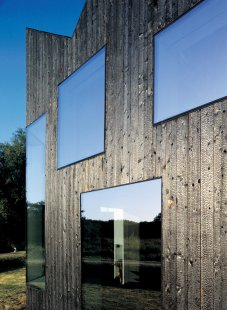

Much like the original cottage, openings are arranged to first respond to the internal configuration. Every room is flooded with natural daylight and blessed with framed views of the windmill and surrounding landscape. Glazing in the kitchen rests on the worktops and permits views to the garden. Fixed panes of glass form a continuous surface with the cladding, to integrate with the geometry of the exterior and assure the airtightness of the interior, which relies instead on regulated stack effect ventilation through openings in the roof.

ECOLOGICAL LANDSCAPING

Flood defense

The marshes behind Hunsett Mill are considered an environmentally sensitive area and part of the Broads National Park. Though attempts have been made to cultivate the land in the past, it was decided that the land should be returned to its natural marshland state, under a ‘Higher Level Stewardship’ agreement with Natural England. The resulting higher water levels would have increased the risk of flooding the Hunsett Mill and the cottage, compelling the owners of the site to construct a series of flooding countermeasures as an integral part of the project. The mill, cottage, and low-lying marshes were previously protected from flooding by an embankment running parallel to the river, starting from Sutton Broad and running some 5km upstream to Wayford Bridge. In recent years the condition of the flood bank has progressively worsened, resulting in instances of flooding at Hunsett Mill and the adjacent fields and forests.

Given the difficulty in access, and poor ground and material conditions it was decided that the most sustainable scheme would be to abandon the existing line of defense downstream of Hunsett Mill and to construct a new bank immediately behind the buildings. The new flood bank is a small, secure, and easily maintainable defense while at the same time allowing the abandonment of subsequent downstream defenses, thereby returning 25 hectares of forest and grassland around Hunsett Mill to its pre-industrial marshland condition.

This land will form an extension to the adjacent Sutton Fen Nature Reserve of the RSPB, adding to the existing tranquil oasis of wetland wilderness, full of rare and endangered wildlife in the midst of the hustle.

The garden

The landscaping strategy for the garden is based on the use of local species in order to blend with the local ecosystem, yet to create a controlled appearance and frame the architecture. A wide selection of species has been used to design flowerbeds around the house and along the river. The color and spread size of each plant has been arranged according to the use of the garden: tall plants have created privacy while short bushes have framed views of the Mill from the river. Different color schemes have created spaces with different identities within the garden. The perennials will change their appearance with the seasons; hence the garden will blend in with the surrounding landscape at any time of the year. Using a large variety of indigenous plants had the effect of boosting the biodiversity of the site.

SUSTAINABLE MATERIALS

Embodied energy

With a desire for the new intervention to be as ecologically responsible as possible, emphasis was placed on the carbon cost of construction and the overall embodied energy expenditure at the time of construction. Materials throughout are sustainable, simple, and natural. The use of materials has been reduced to an absolute minimum by engineering out superfluous material. The structure is entirely made from solid cross-laminated timber walls, slabs, and roofs. This material possesses manifold advantages. As well as acting as the primary structural element, the material functions as an effective insulating member, and also as thermal mass to regulate the internal temperature of the dwelling, reducing the need for nighttime heating. No internal cladding has been used as all timber is left exposed. The timber is FSC certified, meaning it is harvested from sustainable forests where more trees are planted than felled, the welfare of those producing the material is assured, and the reasonable maximum travel distances for the transport of materials are enforced. This verifiable life-cycle approach to the material assures that the house functions as a carbon sink, where the carbon content of the wood is counted against any other carbon cost in the build, and is only returned to the atmosphere when the material is burned as biomass fuel at the end of its life.

Structurally, the stiff “folded plate” of the roof was used in conjunction with the first-floor internal timber panel partitions to suspend the first-floor timber floor plate from the roof, increasing the amount of open space on the ground. A lightweight factory-produced structural solution reduced heavy plant requirement on site, allowing the foundations to be reduced to small diameter driven piles with virtually no piling mat requirements apart from leveling (16). The use of concrete was restricted to the ground bearing slab that sits in the floodplain. In this way, the extent to which the earth was broken was minimal, and no by-products were released into the ground or river, safeguarding the ecological balance of the immediate context, as per the requirements of EMP3.

The laminated timber core of the building is an inherently low-waste system. By designing and fabricating components off-site using a process of computer-driven specification and CNC milling, waste and abortive work was marginalized. This system also respects the welfare of the laborers working during the build. Levels of risk to the safety of personnel, the presence of plant noise and dust were much lower compared to builds using traditional techniques.

The building has high standards of insulation, airtightness, solar control glazing, and high thermal mass. To weatherproof the building in a low-maintenance rainscreen cladding, we adapted a centuries-old, but mostly forgotten, technique of timber preservation, known as superficial charring. In Hunsett Mill, cedar boards have been chosen for their superior longevity and charred to create a surface finish that is humane, tactile, and natural, free of chemical treatments and with a very modest maintenance requirement. The charred cladding creates a contrast in color with the brick construction of the mill cottage and contributes to define a clear distinction between the original and the extension. The rough texture of the charred boards contrasts with the crisp details of the mirrored frameless windows. The blackness also references the tradition of tarred utilitarian buildings one still finds in Norfolk today.

Yakisugi (Charred timber)

Charred timber in the Norfolk vernacular and today

Charring was traditionally used as a method for preserving timber used for boat quays and quay headings, where the timber was submerged in water and the charring sealed the wood. Charred timber is not widely used any longer and the craftsmanship of charring has faded away from knowledge.

Charred timber in Japanese vernacular and today

In Japan charring has a long tradition and has been used to preserve timber cladding and increase its longevity. The charring seals the surface of the timber and burns out a number of oils that usually attract insects, leaving behind a black-silver surface layer of carbon/coal that protects the board. In Japan’s construction industry, charring is a fairly common practice where specialized manufacturers produce charred timber in a semi-industrial way. This ensures the quality is high and consistent throughout the production process and results in an economic product.

Charred timber at Hunsett Mill

Attempts to source charred timber locally to clad the new extension failed for a number of reasons: The charring was carried out manually using a propane gas-powered blowtorch which created only light superficial charring whilst using energy in a wasteful way. Samples showed that the quality of the charring was poor and would have resulted in flaking of the char. For quality, environmental, but also economic reasons, it was therefore decided to use imported timber for the external rainscreen cladding. The charred boards were sourced in Japan, providing a product of a higher quality but still lower cost than possible to source in the UK. Japanese charred timber also proved to be more sustainable during its manufacture; its transport used shipment to the UK. Two types of charring have been used to clad the new extension. The roof cladding boards were first charred and subsequently sandblasted. The vertical cladding boards are charred silver only.

ENERGY

Low-Tech and High-Tech

Where possible, the building takes a decided ‘low-tech’ approach to its internal environment and servicing. Orientation, insulation and fabric, and the positioning of windows maximizes internal daylight. The heart of the house is a double height area, flooded with light, affording dramatic views of the wilderness outside. The fundamental design move was to ensure maximum daylight and solar exposure during the winter months to benefit from free solar passive heating. Conversely, passive stack ventilation and argon-filled ‘Pilkington SunCool’ solar control glass prevent summer overheating. By leaving the internal surfaces of the laminated timber as a finish, its thermal mass capacity is best utilized, to harness the heat from solar gain captured during the day for steady release in the evenings. To precipitate natural ventilation in warmer months, several double-height spaces with individually controlled outlets create stack effects, drawing in fresh air. These passive techniques, married with the use of self-sufficient heating and servicing facilities, create redundancies so that the internal environment of the new extension is always pleasant while consuming a small fraction of the energy of the spaces it replaced.

Self Sufficiency

Hunsett Mill operates almost independently; electricity is the only off-site resource connected to the property. Nonetheless, the use of energy-efficient and motion-activated fixtures assures that electrical consumption is very low relative to the size of the house. The occupant sources electricity from ‘Good Energy’, the only wholly renewable energy provider in the UK. Not only can this be considered better for the environment than on-site per-dwelling micro-generation in certain circumstances, it also helps support and promote such companies as a realistic alternative.

Passive design strategies reduce dependency on artificial heating for much of the year, yet during the winter months, a wood-fired stove is used as required as a carbon-neutral method of maintaining internal comfort.

Fuel is harvested from the garden and local woodland by the occupant. Hot water and central heating requirements are catered for in two ways. Firstly, the property employs a Viessmann ground source heat pump.

The site has a very shallow water table; as a result, the buried slinky pipes have excellent ground coupling connectivity and will enable the heat pump to operate at maximum efficiency. Underfloor heating is used throughout with zonal controls providing local temperature control and monitoring. While the heat pump installation is very simple to use, a reduced form operating guidance sheet is provided in the utility room. This compliments the full operating and maintenance manual provided to support all the systems. Secondly, domestic hot water provision is complemented by the inclusion of 2 square meters of high-performance vacuum tube solar thermal collectors to the roof, providing up to 60% of the domestic hot water requirement of the property. This equates to a 6% contribution in terms of overall renewable contributions.

Water management

Hunsett Mill operates in total independence with regards to water management. Fresh water is sourced from a dedicated domestic water borehole located within the garden, with the associated pumps and filtering located within the property’s riverside boathouse. The owner has minimized water usage by the use of efficient fittings – toilets are dual flush, domestic appliances are AAA-rated and water connections are ‘low flow’. In spite of these measures, the use of fresh water is further minimized by capturing rainwater on site, harvested via the nearby windmill pond. The water is used for irrigating the local planting and garden. Foul waste is treated on site via a low maintenance extended aeration treatment tank. This system processes effluent in a self-contained chamber designed to actively encourage bacterial breakdown of sewerage. The system operates purely on gravity and has no moving parts. The final discharge is into the adjacent watercourse with full EA and Broads Authority consent.

The English translation is powered by AI tool. Switch to Czech to view the original text source.

0 comments

add comment